Performance and Precision: Mayo Clinic’s Phoenix Campus

The Integrated Education and Research Building (IERB) at the Mayo Clinic’s Phoenix Campus stands as a beacon of innovation in medical research and training. Designed to foster collaboration among students, educators, researchers, and clinicians, the building features state-of-the-art labs, classrooms, and flexible workspaces - all wrapped in a high-performance façade that reflects the facility’s forward-thinking mission.

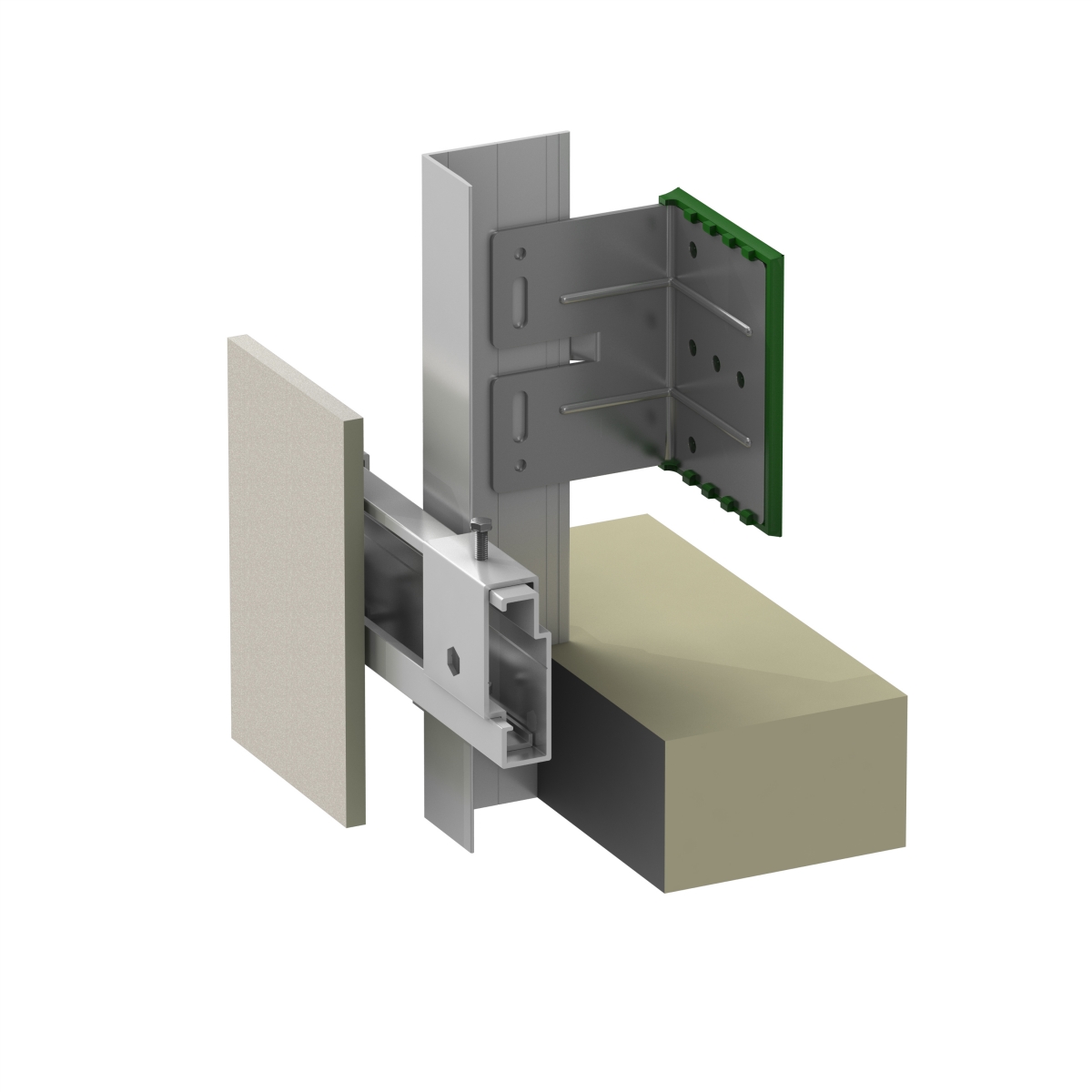

To achieve the aesthetic and durability standards required for this landmark project, the design team selected Ceramic5 Ceramic Stone Panels, a visually sophisticated and weather-resistant ceramic stone cladding option made from natural raw materials. Behind those clean lines and low-maintenance surfaces, however, lies a powerful support system: the ECO Cladding Vci.40 sub-framing system.

Precision Meets Performance: Sigma Vci.40 System Advantages

The Vci.40 System from ECO Cladding is more than just a subframe - it’s a fully engineered rainscreen support solution designed to simplify installation while enhancing thermal, structural, and fire performance. Here’s why it was the ideal choice for the IERB:

- Built-in Adjustability - With up to 1.5" of internal adjustment, the Vci.40 system allows installers to easily achieve a level and plumb installation, even when working with varying cavity depths from 2" to 12". This built-in flexibility reduces on-site labor and improves alignment accuracy.

- Universal Bracket Efficiency - The system’s universal bracket supports both horizontal and vertical orientations, streamlining the installation process and reducing the number of components needed.

- Engineered stiffening ribs improve overall strength and load distribution - ideal for heavy panel applications.

- Thermally Broken for Efficiency - A pre-installed isolator pad acts as a thermal break, helping to significantly reduce heat transfer and minimize thermal bridging. The system supports energy goals such as ASHRAE 90.1 compliance and Passive House standards, contributing to long-term operational efficiency.

- Non-Combustible & Code Compliant - Manufactured from Grade 304 stainless steel, the Vci.40 bracket system is non-combustible and built to withstand high wind loads and seismic forces—delivering essential peace of mind in fire-prone regions or where stringent building codes apply.

- Sustainable & Made in the USA - Sustainability was a key focus in the selection of system components. The Vci.40 brackets feature an excellent recycled content profile - with 18.29% pre-consumer and 63.77% post-consumer recycled material. Additionally, the system is made in the USA, aligning with Buy America / Buy American project requirements.

Engineered to Perform

The Vci.40 system is carefully designed to address a range of structural considerations, including dead load, wind load, seismic activity, and thermal expansion. Its combination of fixed and sliding points allows the façade to expand and contract without sacrificing stability or alignment, ensuring long-term durability and aesthetics.

The Mayo Clinic’s IERB is more than just a building - it’s a commitment to innovation, collaboration, and performance. With the combination of Cladding Corp's Ceramic5 porcelain panels and the ECO Cladding Vci.40 System, the project achieves not only a sophisticated, modern appearance but also a high-performing building envelope ready for decades of use in Arizona’s demanding climate.