Continuous Insulation (c.i.), as defined by ASHRAE 90.1, is an increasingly significant consideration in building design. The topic of continuous insulation is relevant for all types of construction but has been of recent interest within the context of commercial construction. It is considered best practice, whether the building in question is a residential or commercial structure but there remains considerable confusion about how to design with continuous insulation in mind.

C.I. IS ALL ABOUT U!

Industry confusion around continuous insulation or (c.i) continues to persist. The best, most comprehensive approach to evaluating a wall’s thermal performance is to thermally model the wall’s U-Value. The required U-Value depends on the building’s location and corresponding code adoption. All ECO Cladding systems incorporate intermittent Alpha brackets with aluminum rails to create the “C.I. Subframing” layer. The exterior “Panel Subframing” is then attached back to this layer to create a complete rainscreen system.

Morrison Hershfield, an industry leader in thermal modeling, has analyzed the Alpha bracket configuration on steel stud walls with “C.I. Subframing” on two wall types: split insulation and exterior only insulation. To assist the design community, multiple thicknesses of the three most common insulation materials (mineral wool, polyiso exterior boards, and polyiso spray foam) have been modeled. Using the ECO Calculator, the layout can be determined and the corresponding wall’s U-Value can be provided.

C.I. just got a whole lot simpler.

ALPHA BRACKET EFFICIENCY

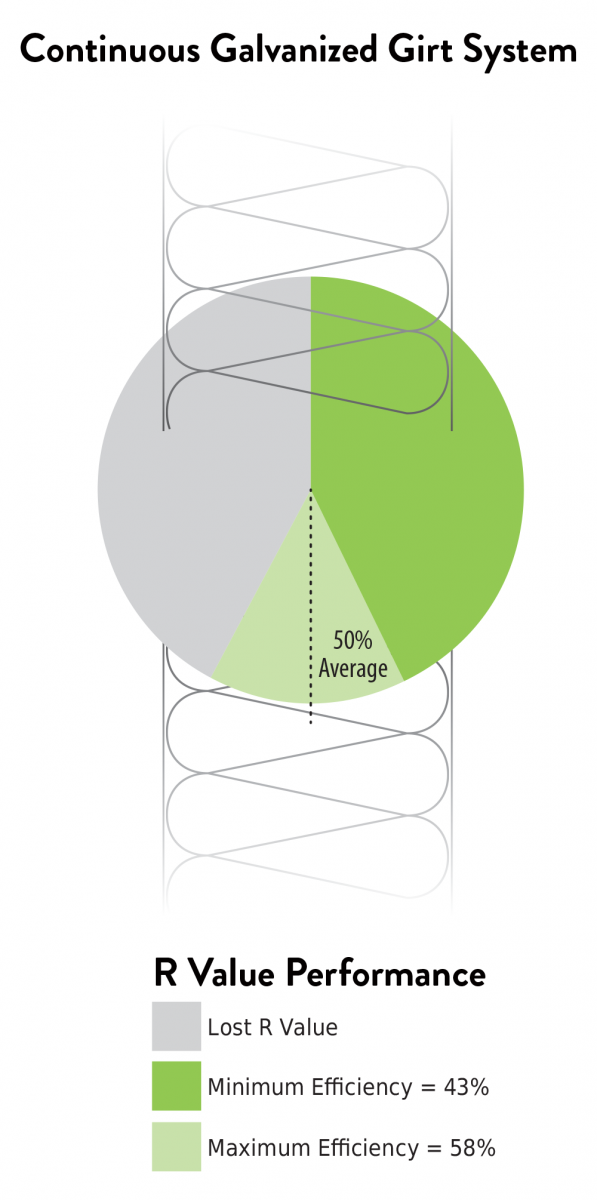

The best way to isolate the impact of interior framing on a wall’s thermal performance is to evaluate a wall without batt insulation so that the thermal analysis can focus on the impact of exterior insulation. For years, the construction industry has used continuous galvanized girt systems, attaching at every stud (16” o.c.) and at every 24” o.c. moving up the façade. Unfortunately, this approach causes the average insulation effectiveness of 50%, and half of the wall’s thermal performance is wasted. The strength of aluminum Alpha brackets allows spacing of brackets to typically be twice the range of other subframing systems. In addition, the smaller bracket sizes enable a very low impact on the wall’s thermal conductivity. Alpha brackets can move insulation’s effectiveness by up to 93%.

Consult your ECO Cladding representative for the appropriate bracket layout for your project based on the wall’s desired U-Value.

Below are some common questions regarding ECO Cladding's design approach and how it will enable you to achieve your energy efficiency goals.

What is the ASHRAE 90.1-2010 definition of continuous insulation?

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) standard 90.1 defines continuous insulation (ci) as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.” This means any form of insulation discontinuity greater than a masonry tie or screw does not meet the definition of “continuous”.

Is it reasonable to believe that you can only use a screw or masonry tie as the primary structural support element for cladding in commercial construction?

For Residential and Type V construction under low wind load conditions (less than 18 psf), this may be a viable option. With commercial construction, however, this is not an adequate, long-term structural solution. A masonry tie used without a steel shelf angle or a screw cantilevered through 2 or 3 inches of insulation will not resist the rotational forces created by dynamic wind loads, seismic loads/deflections, and material dead loads commonly seen in multi-story commercial construction.

How can a commercial design meet the definition of “continuous” as defined by ASHRAE?

ASHRAE acknowledges that adequate structural elements are essential to support the weight of the exterior cladding elements, and to address building movements, seismic loads and dynamic wind forces on the cladding. Since there are various approaches to the design of the support systems – specifically with regards to how often the elements of the system penetrate and interrupt the envelope insulation – ASHRAE redirects the continuous insulation requirement to Appendix A of the ASHRAE 90.1 code. This section of the code outlines the criteria necessary when proofing the performance of the exterior envelope (backup wall and exterior cladding) with approved thermal modeling programs to determine the effective R-Value of the exterior envelope.

Given the thermal modeling approach, what attachment methods are preferred?

From a performance aspect, the ultimate goal for any high-performance thermal envelope is twofold: First, to eliminate or significantly reduce the opportunities for thermal bridging that can cause a loss of effective R-value and second, to reduce sources for air leakage through the membrane and insulation plane that can allow heat migration inward or outward of the conditioned spaces of an occupied building. Therefore the best solution is to engineer a support assembly that will effectively address all structural loads and minimize penetrations through the insulation and membrane.

What are the benefits of a bracketed system? (Why is a bracketed system best?)

A corrosion-resistant aluminum bracketed system can span greater distances between attachment points, thereby minimizing the penetrations through the insulation and membrane, while still supporting structural loads. This approach offers a very efficient thermal design as compared to other materials considered acceptable under ASHRAE’s definition for continuous insulation. In general, a bracketed support system has shown to maintain between 91% to 98% of the initial effective R-value of the insulation used, and will not require additional insulation thickness to meet code as compared to a theoretical envelope that had no penetrations. Since ASHRAE legitimizes the use of thermal modeling programs for Type I thru IV construction, a bracket system modeled to achieve the performance requirements of ASRAE 90.1 is the best option for high-performance exterior envelope designs.