Sigma Bracket - Stainless Steel

Not just universal... address your building’s U-value with Sigma U Brackets.

Thermal bridging can be responsible for a structure’s heat loss. What is a 'thermal bridge'? The calculations around thermal bridges are rather complicated and intricate, but essentially, thermal bridges are the points at which conventional building design loses energy. They are often unaccounted weak points in the building envelope resulting in high local discomfort, moisture, and mold while providing a highway for energy loss.

ECO Cladding’s Sigma U (Universal)* stainless steel wall brackets are designed to address the instance of thermal bridging for certain applications. Sigma U wall brackets feature a soft TPE isolator designed for superior moisture management. The isolator creates a tight seal at attachment points, channeling water away from the building substrate to help mitigate moisture intrusion. With no through-holes in the isolator, it seals penetration points effectively and also serves to isolate dissimilar materials from the substrate, enhancing long-term durability and system integrity.

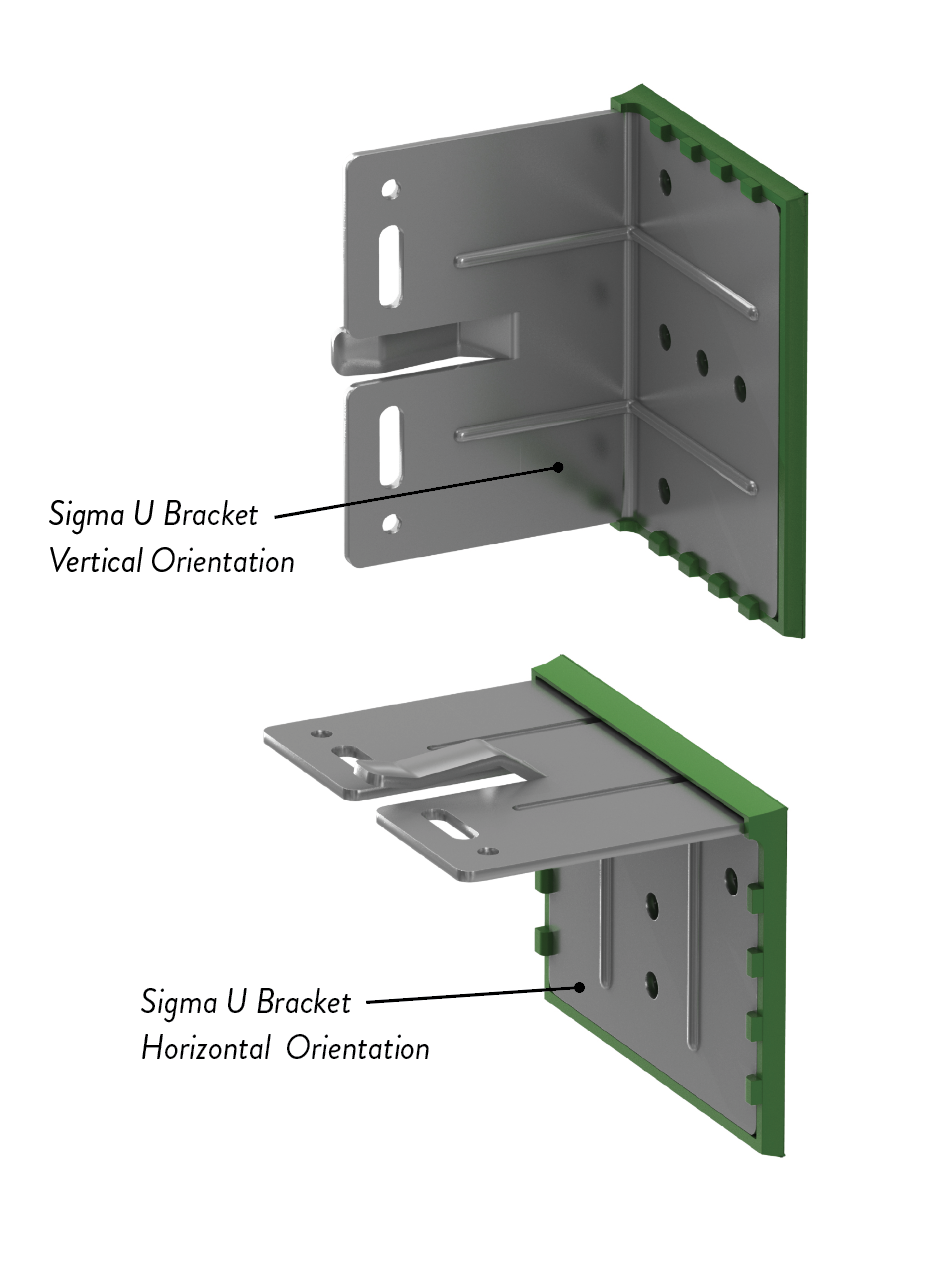

Sigma U Brackets are designed to simplify the building rainscreen walls of all types by providing one ‘universal bracket’ for both horizontal and vertical orientation. Sigma U Brackets are available in multiple sizes to create various cavity depths. The number of fasteners back into the substructure will be optimized based on load requirements and backup wall type.

Key Sigma Features:

-

Thermally Broken System - Made of enhanced thermal-resistant material, Sigma U brackets support energy-efficient wall designs. They help achieve U-values that comply with ASHRAE 90.1 requirements.

-

Self Adjusting - Up to 1.5” of internal adjustability. Level and plumb not a problem. Cavity depths from 2” to 12”. Helping hand acts like another laborer on your team.

-

Universal Bracket - Both vertical and horizontal are achieved in one bracket. Stiffening ribs create optimal engineering design. Our patent-pending design is unique!

-

Non-combustible - Fire resistance to address fire codes.

-

Recycled Content - Sigma U brackets offer an excellent recycled content profile with 18.29% pre-consumer and 63.77% post-consumer.

-

High-Grade Material - Grade 304 stainless steel is pre-punched and accommodates heavy rainscreen panels and high wind loads.

- Made In USA - American-made steel. Buy America / Buy American advantage.

*Patent Pending

Sigma WALL BRACKET SIZES

Available in both vertical and horizontal designs, Sigma brackets are patent-pending and available in multiple sizes to create various cavity depths.

Submit your project to us using our Build Your Project submission process and we can assist!

| BRACKET DEPTH | ADJUSTABILITY | VERTICAL | HORIZONTAL |

|---|---|---|---|

| U.02 | 2.50” – 3.75” | Yes | Yes |

| U.03 | 3.25” – 4.75” | Yes | Yes |

| U.04 | 4.25” – 5.75” | Yes | Yes |

| U.05 | 5.25” – 6.75” | Yes | Yes |

| U.06 | 6.25” – 7.75” | Yes | Yes |

| U.07 | 7.25" - 8.75" | Yes | Yes |

| U.08 | 8.25" - 9.75" | Yes | Yes |

| U.09 | 9.25" - 10.75" | Yes | Yes |

| U.10 | 10.25" - 11.75" | Yes | Yes |

| U.11 | 11.25" - 12.75" | Yes | Yes |

| U.12 | 12.25" - 13.75" | Yes | Yes |