Rainscreen Wall Design has Matured...

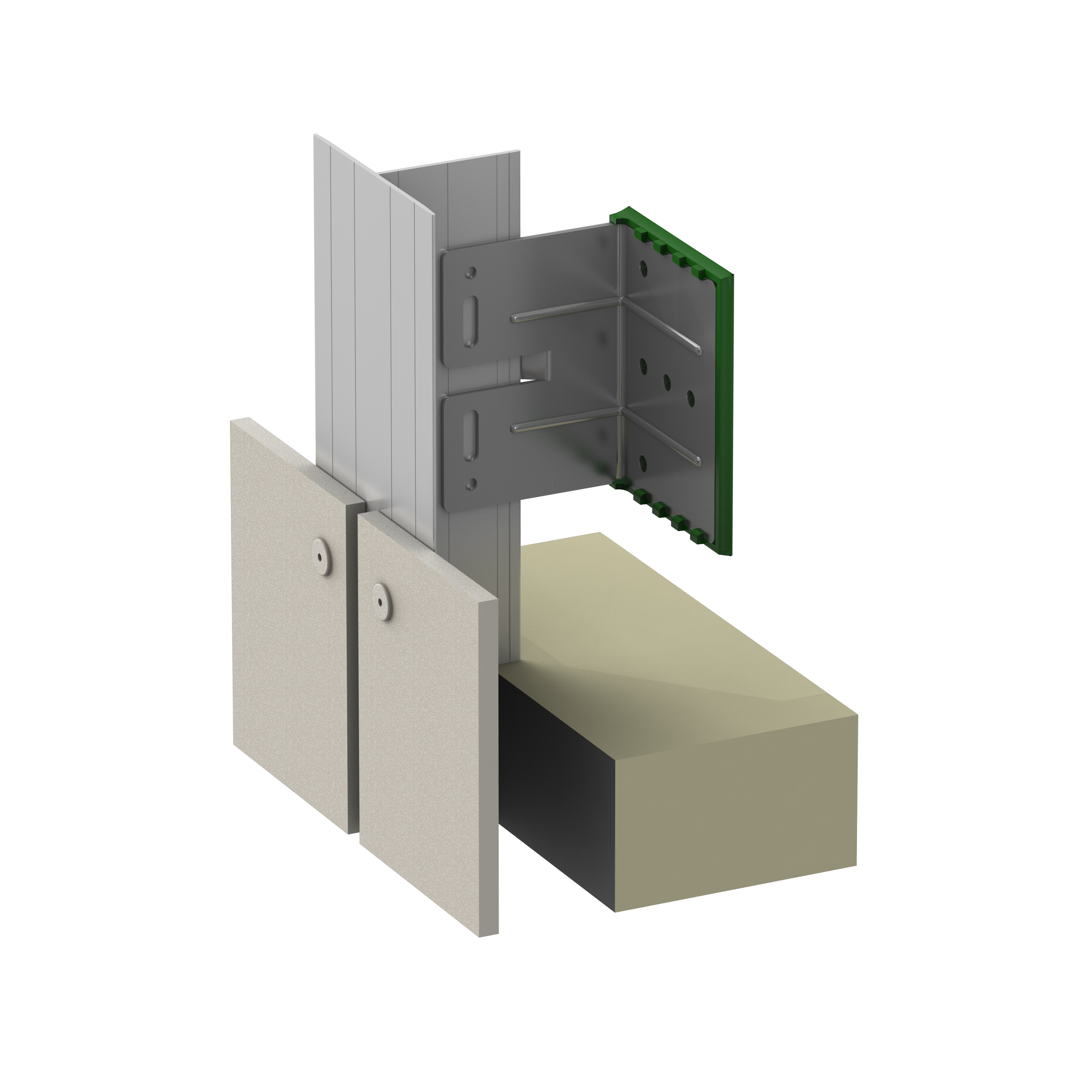

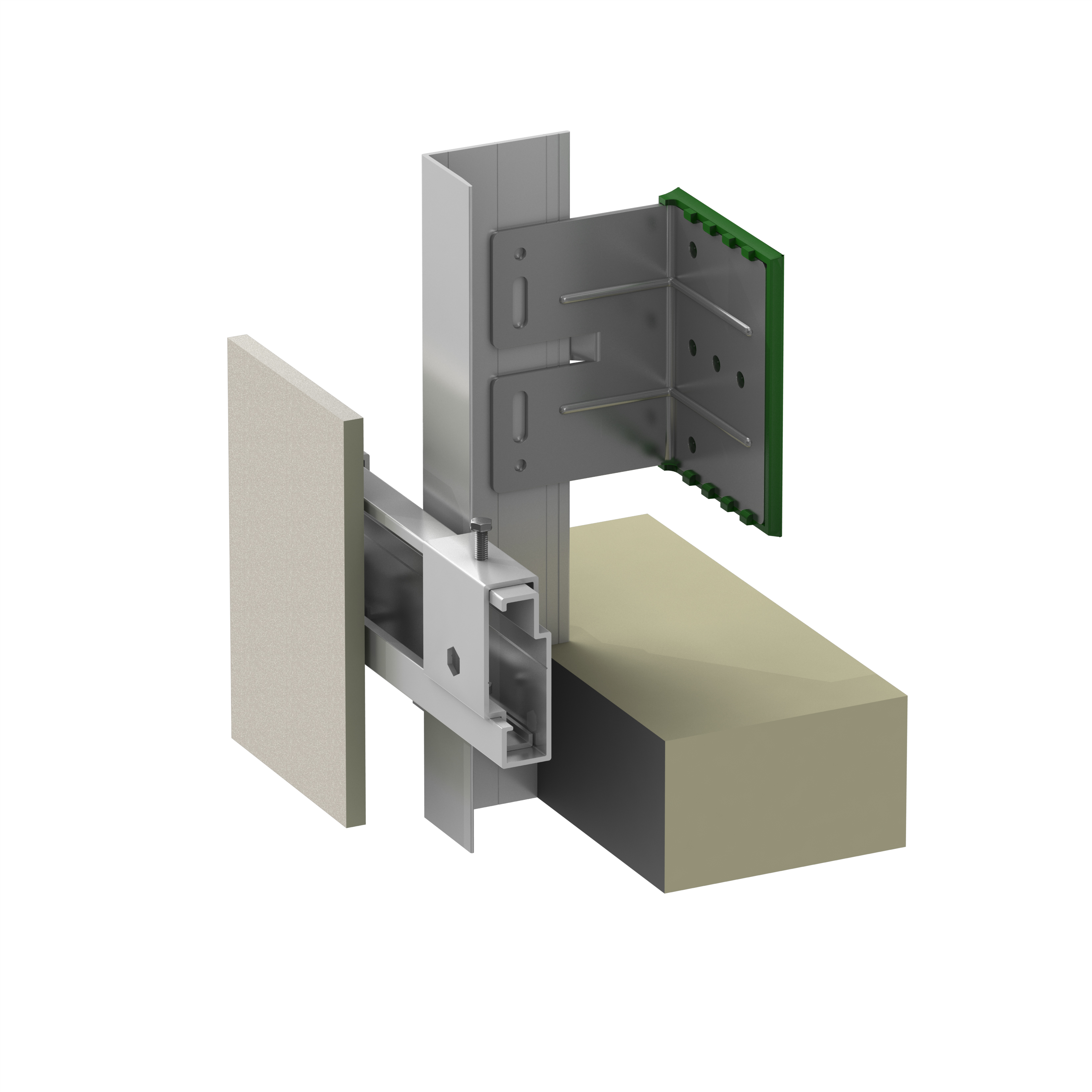

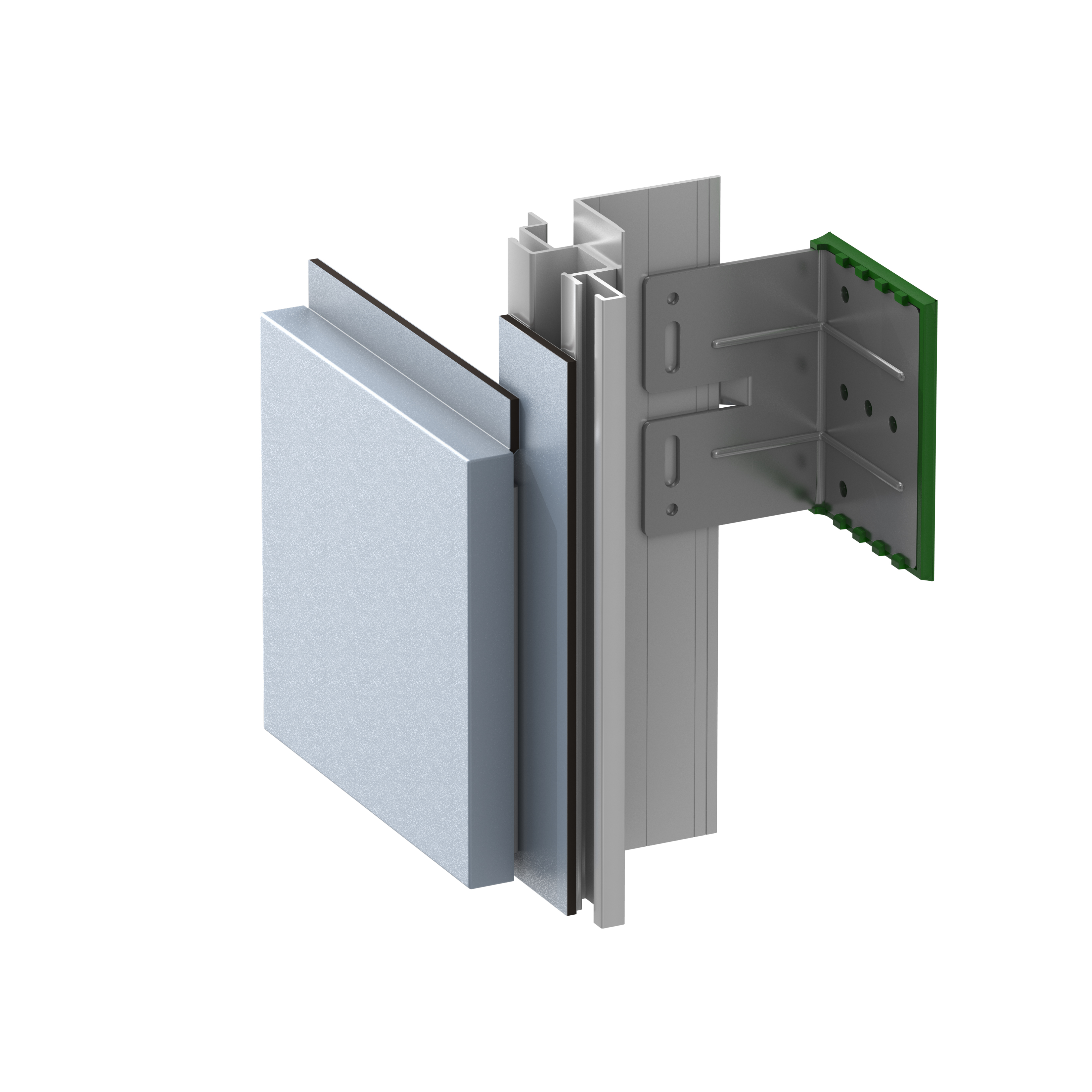

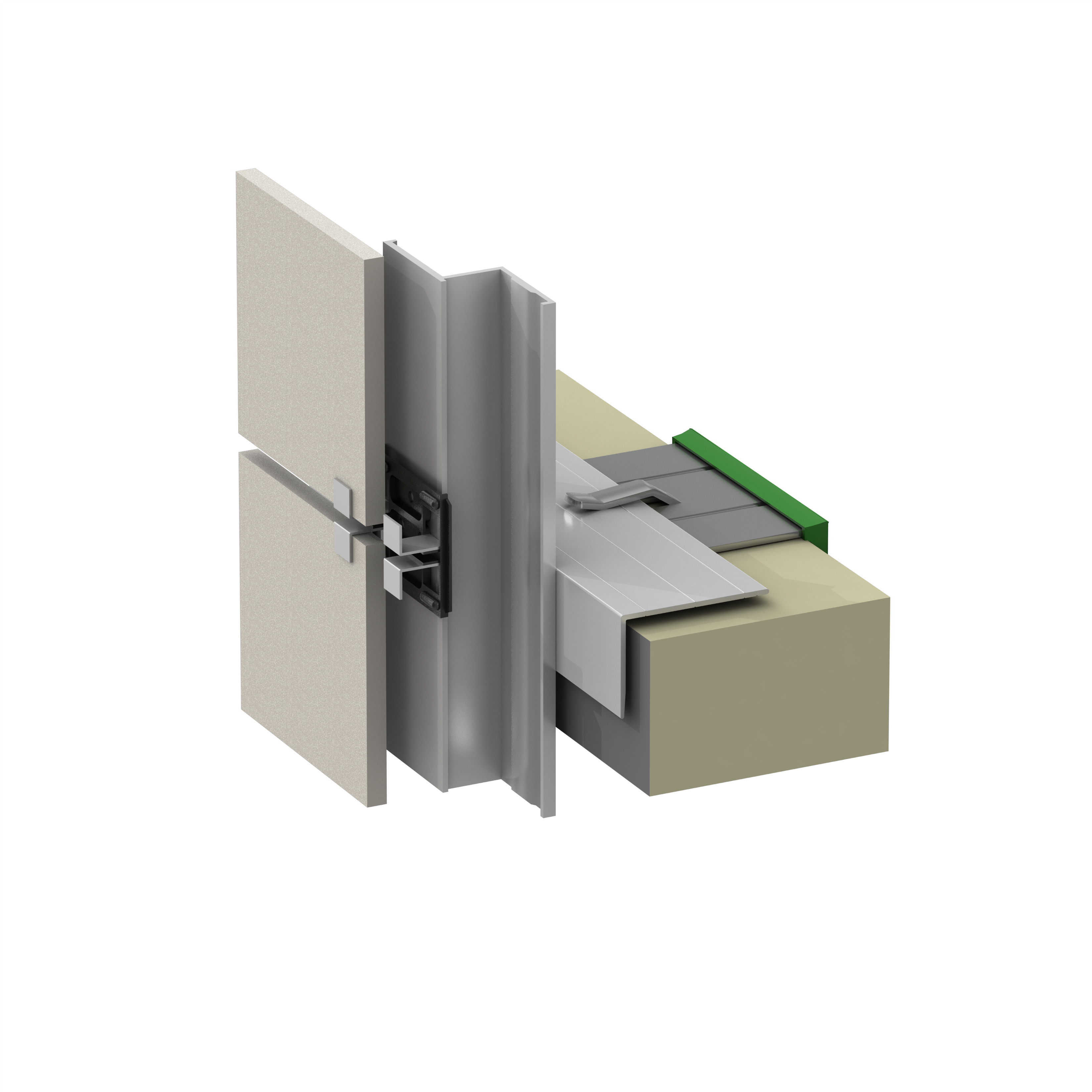

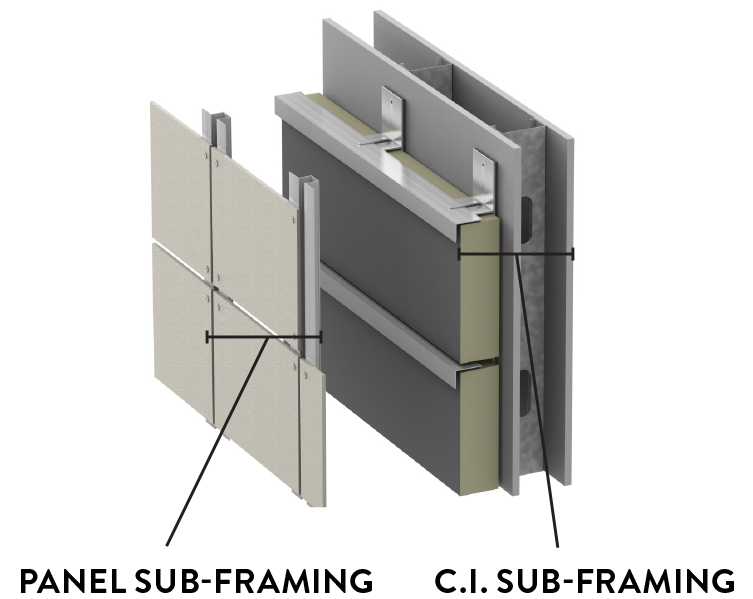

Building designers and owners want a complete, cost-effective wall where all components work together to maximize the wall’s performance. Substrate, air-vapor barrier, insulation, sub-framing, and exterior facade panels need to be designed as one wall assembly with each element complimenting the other. ECO Cladding sees cladding support systems or attachment systems as two parts, what we call “C.I. Sub-framing” and “Panel Sub-framing,” working in harmony to create one unified wall assembly.

With a variety of solutions being offered, ECO Cladding believes that our Sigma stainless steel “C.I. Sub-framing” layer provides the best combination of fire safety, engineering, and thermal performance at a cost-effective price. When the “Panel Sub-framing” is incorporated into the system, the wall assembly will address all of the wall’s design requirements and ensure the façade’s exterior panels achieve maximum performance.

In addition, all of ECO Cladding’s cladding support system components are non-combustible and are not triggers for the NFPA 285 requirements in the IBC.

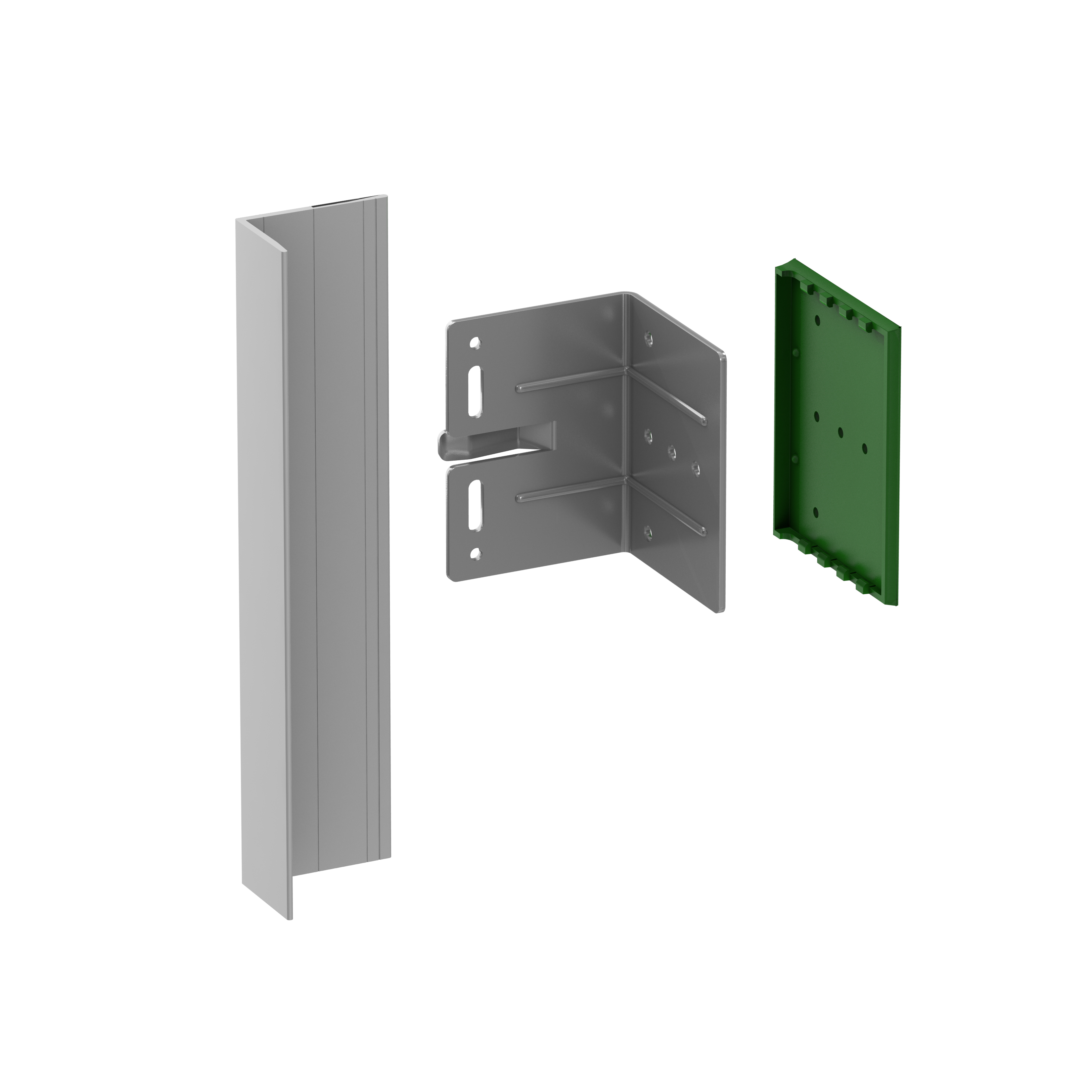

Sigma U: A Universal Wall Bracket Solution

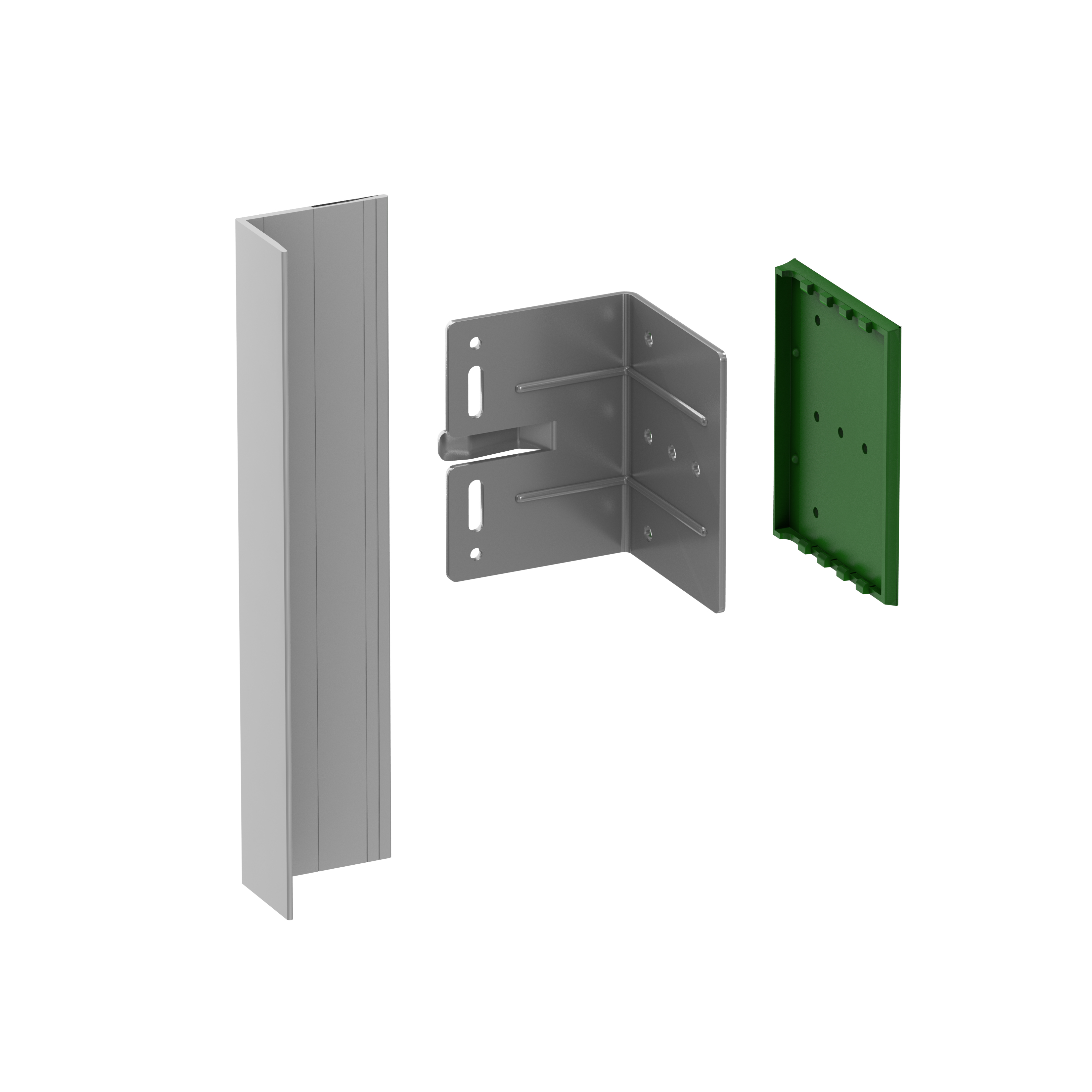

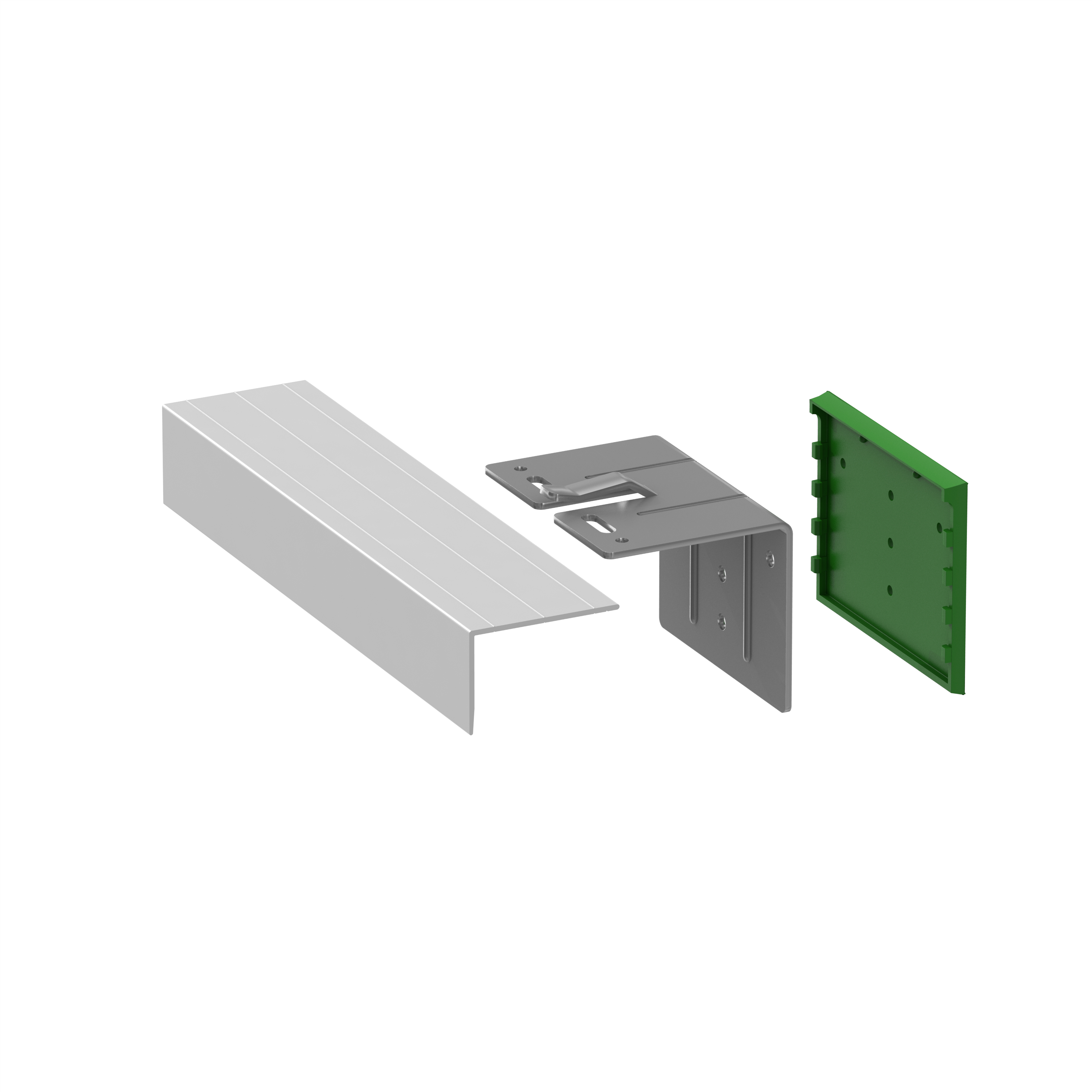

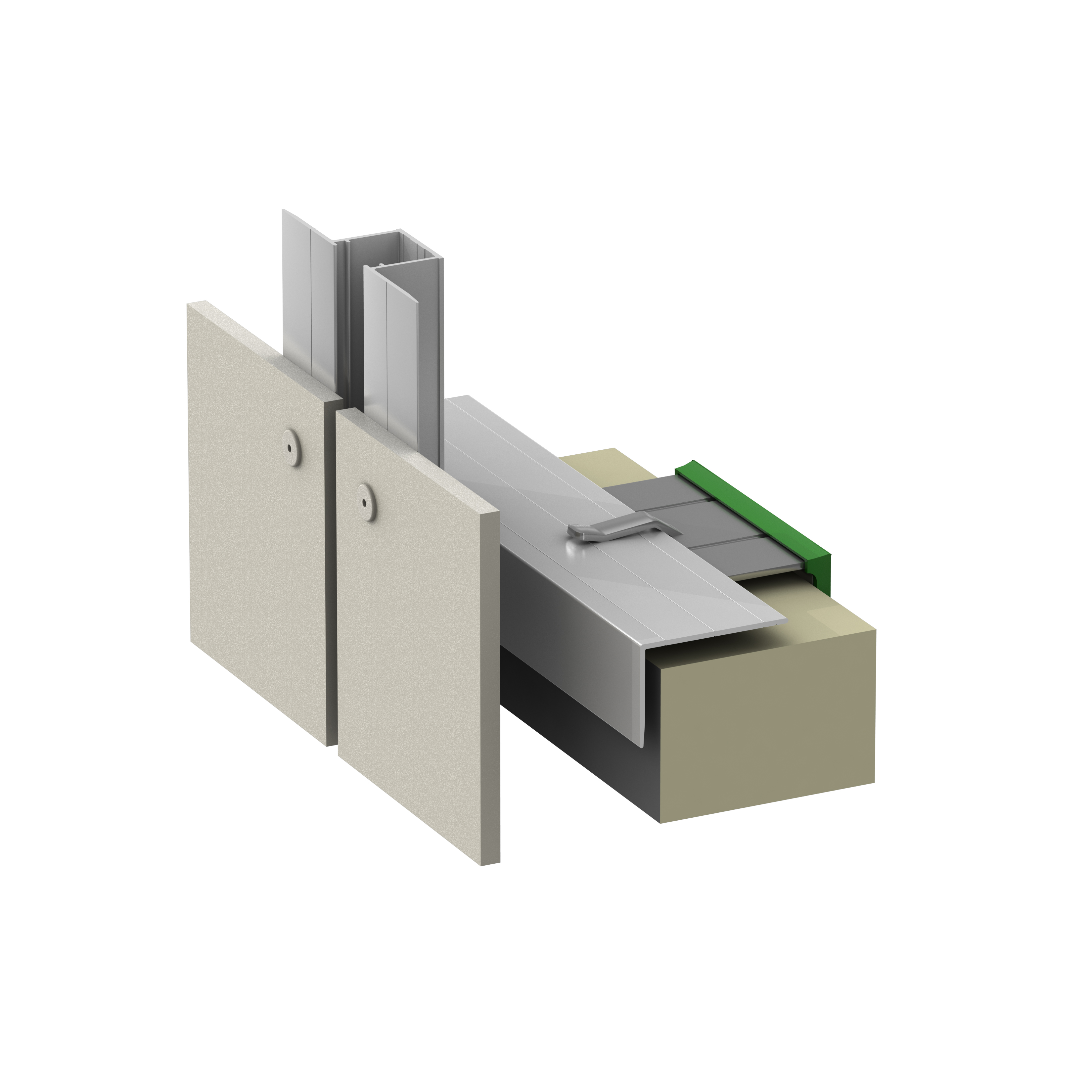

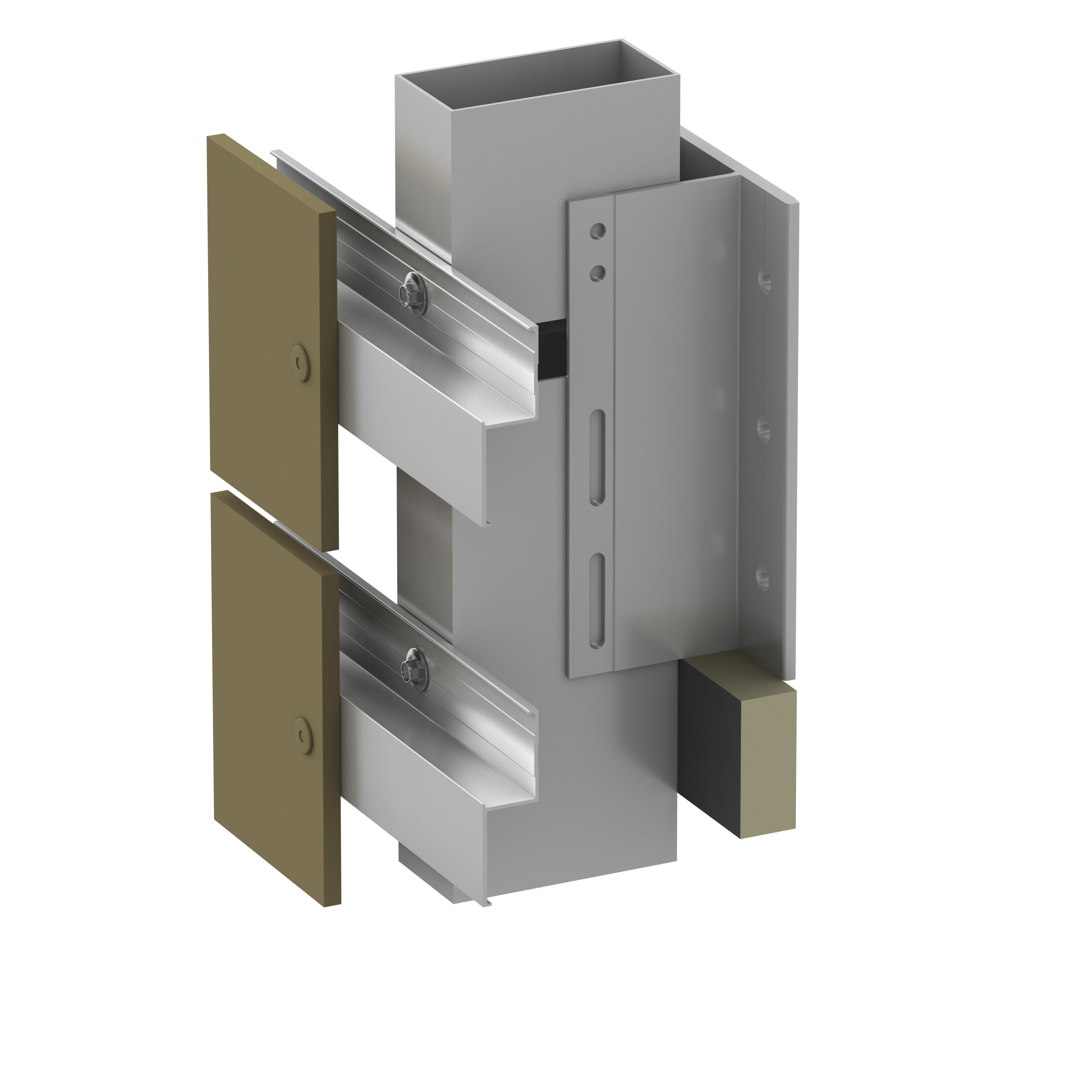

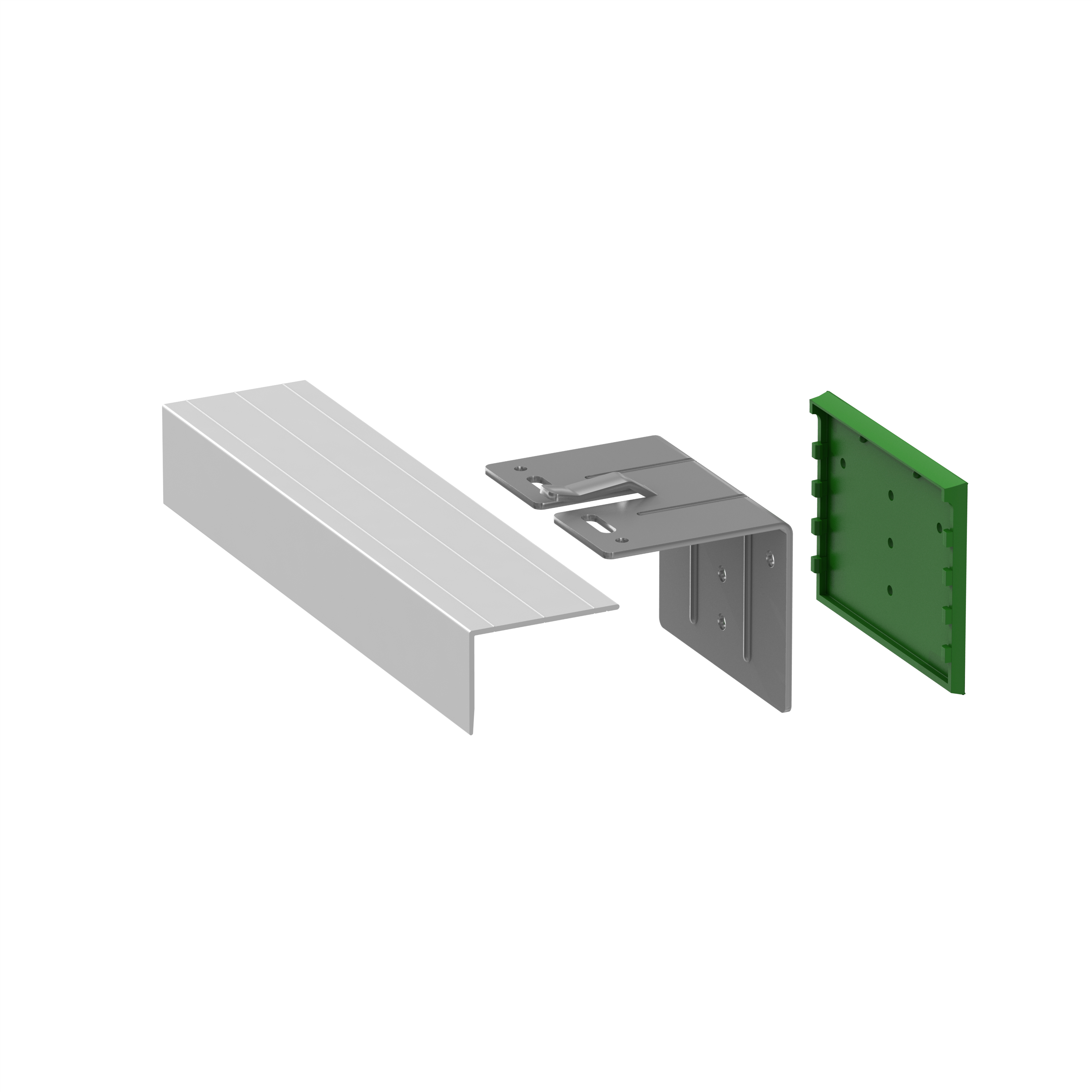

Our patent-pending Sigma U Wall Brackets are designed to simplify the building rainscreen walls of all types by providing one ‘universal bracket’ for both horizontal and vertical orientation. Sigma U Brackets are available in multiple sizes to create various cavity depths.

Start with Sigma U stainless steel wall brackets and then build the C.I. Subframing either vertically (Vci) or horizontally (Hci). The Panel Subframing components will then follow!

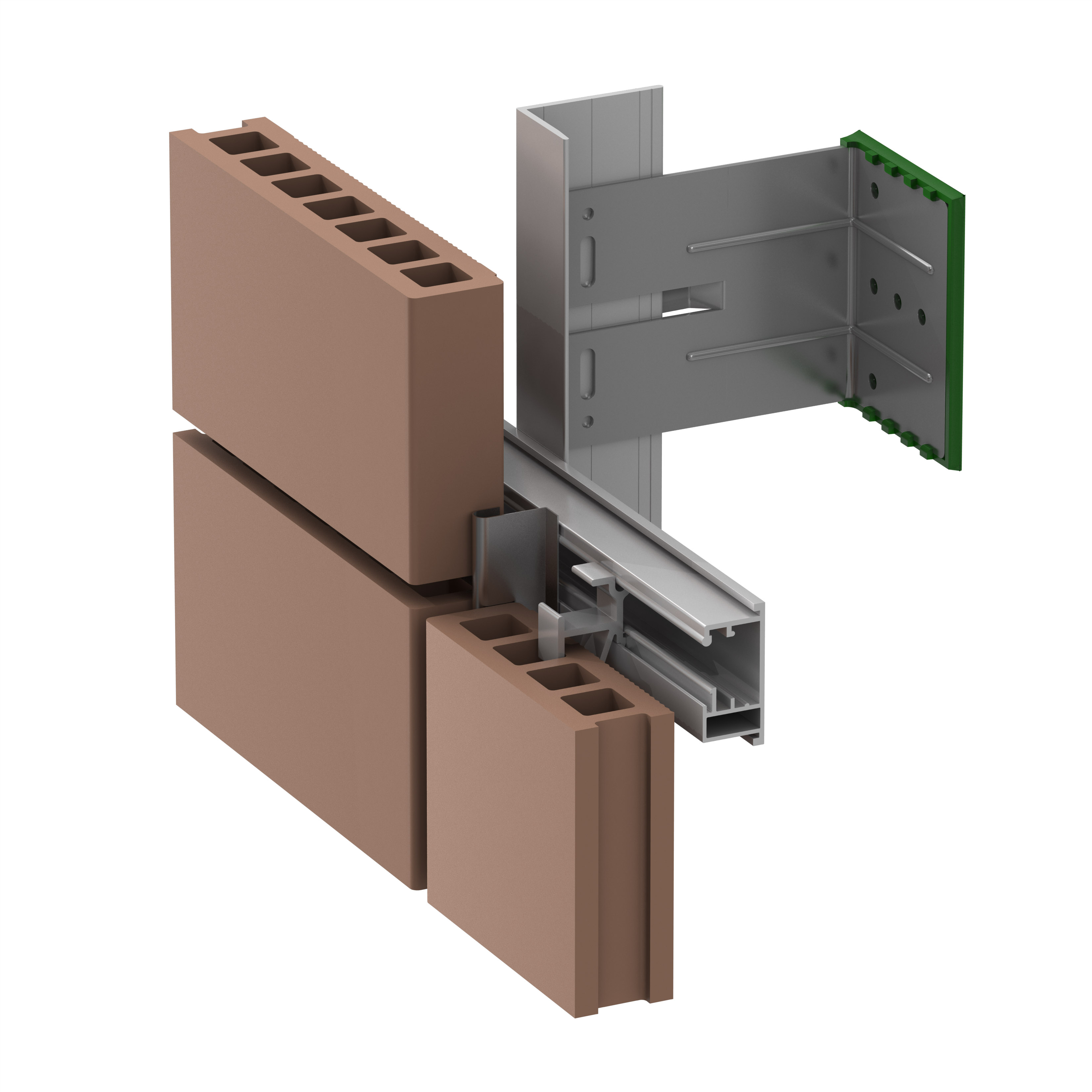

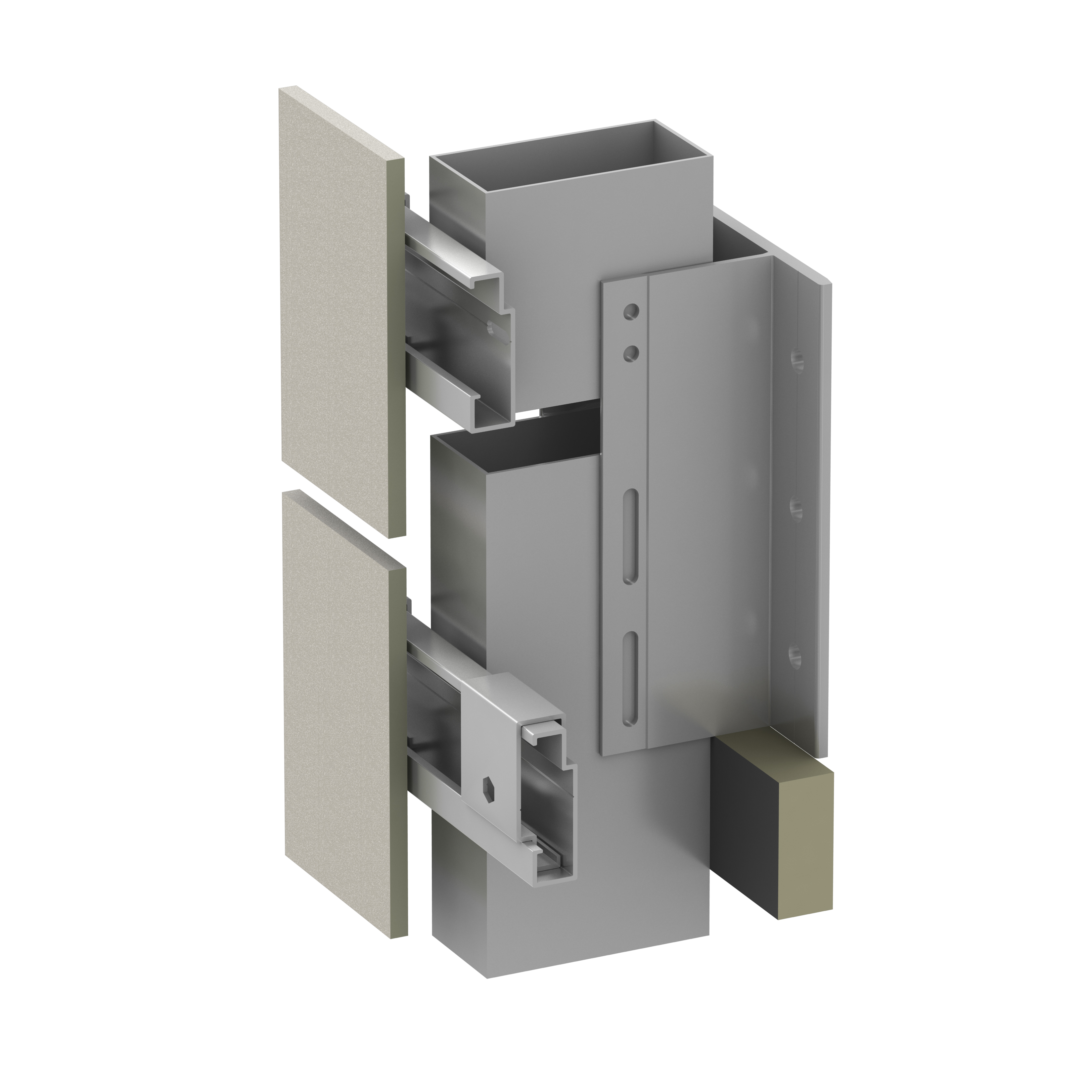

Vertical Orientation of Sigma Brackets - Vci - C.I. Sub-framing System

Vci represents our vertically oriented C.I. Sub-framing systems designed for fire safety, optimal engineering, and thermal performance. Based on the panel layout, this system creates a vertically oriented attachment plane for the panel layout.

Our Sigma Universal wall brackets serve as the engineered building block components for vertically oriented C.I. Sub-framing. Fully engineered and designed to incorporate intermittent wall brackets with continuous outer aluminum rails to create the “Vci Sub-framing” layer.

Wall brackets are available in our Sigma (stainless steel) and Alpha (aluminum) versions. These metals qualify as non-combustible per IBC language.

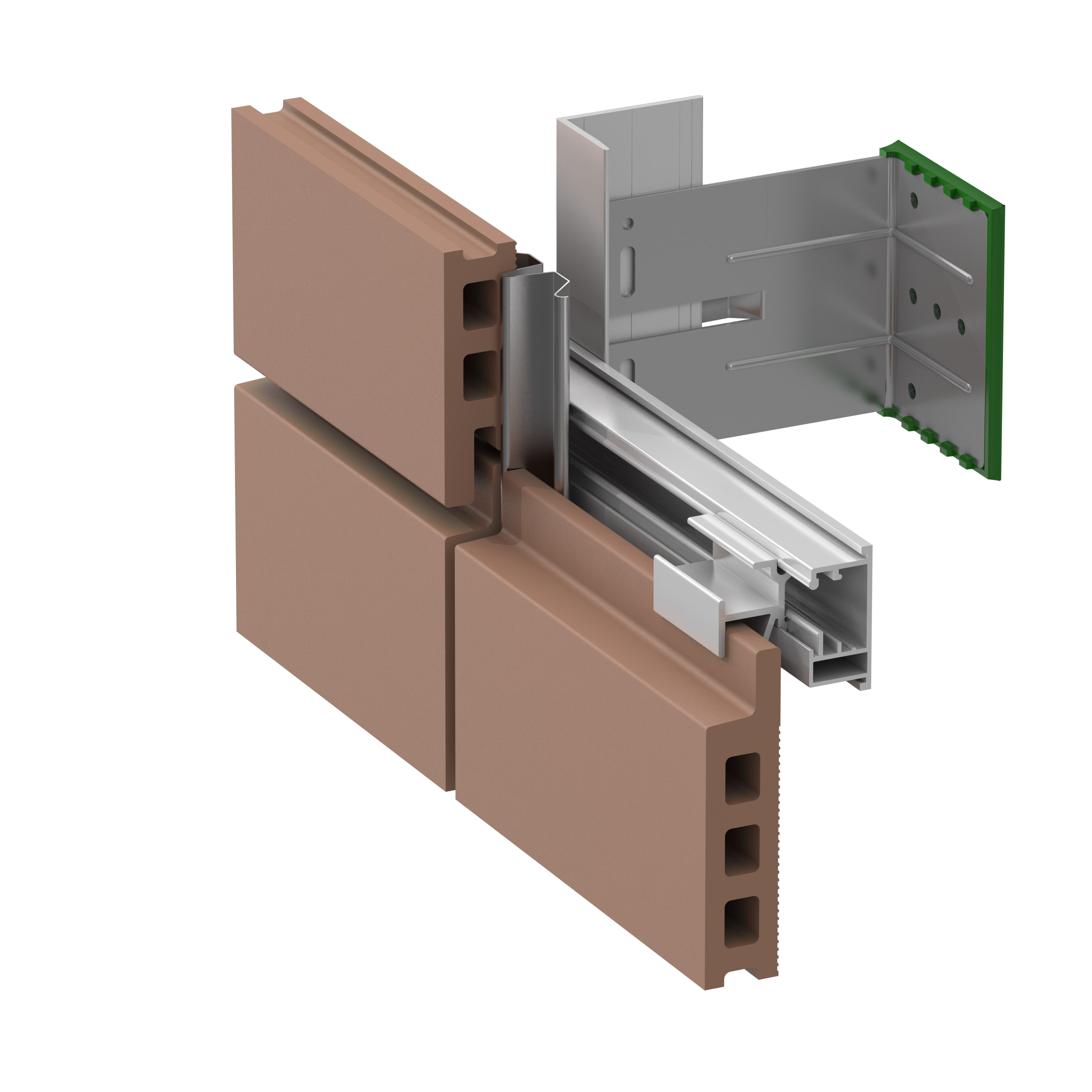

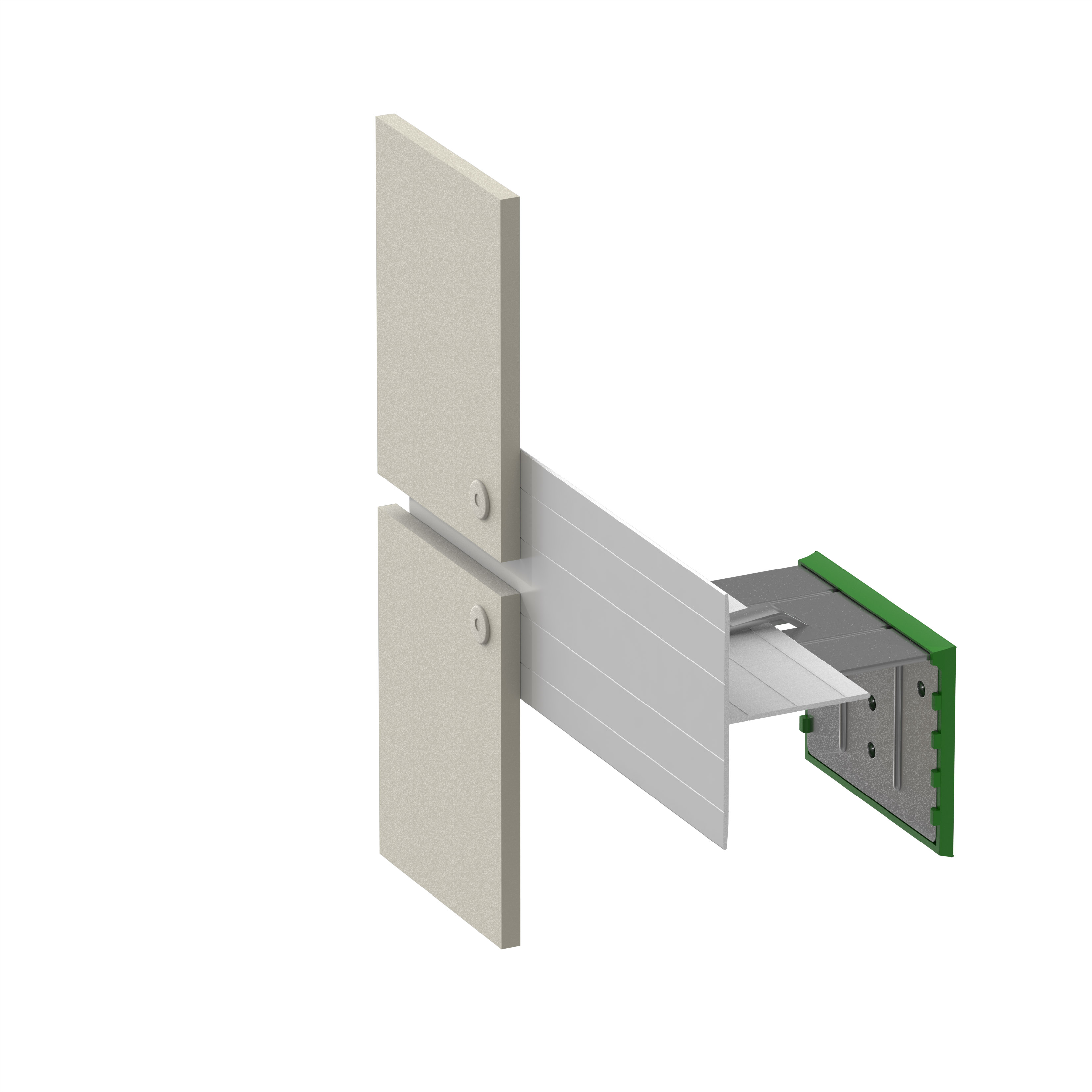

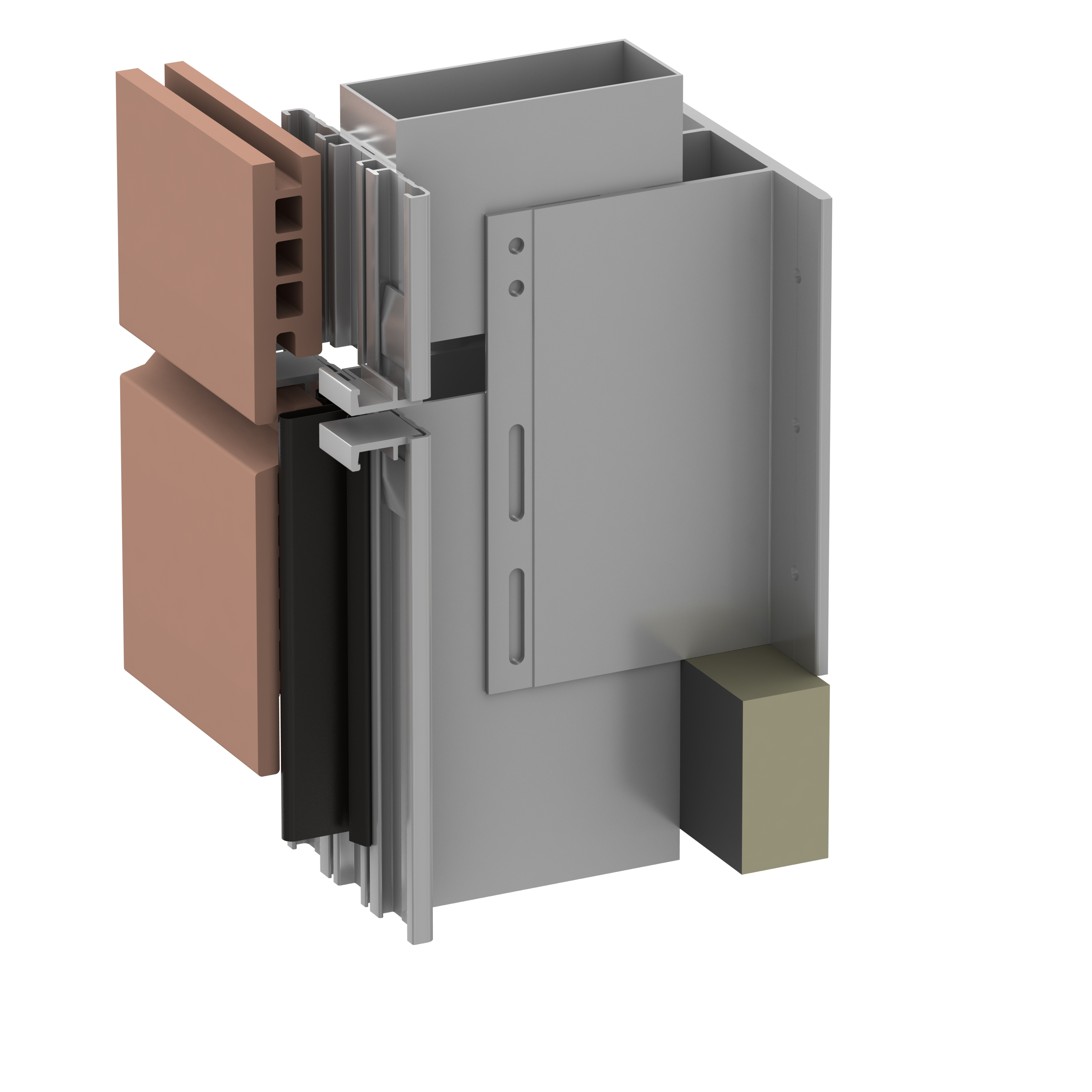

Horizontal Orientation of Sigma Brackets - Hci - C.I. Sub-framing System

Hci represents our horizontally oriented C.I. Sub-framing systems designed for fire safety, optimal engineering, and thermal performance. Based on the panel layout, this system creates a horizontally oriented attachment plane for the panel layout.

Our Sigma Universal wall brackets serve as the engineered building block components for horizontally oriented C.I. Sub-framing. Fully engineered and designed to incorporate intermittent wall brackets with continuous outer aluminum rails to create the “Hci Sub-framing” layer.

Wall brackets are available in our Sigma (stainless steel) and Alpha (aluminum) versions. These metals qualify as non-combustible per IBC language.

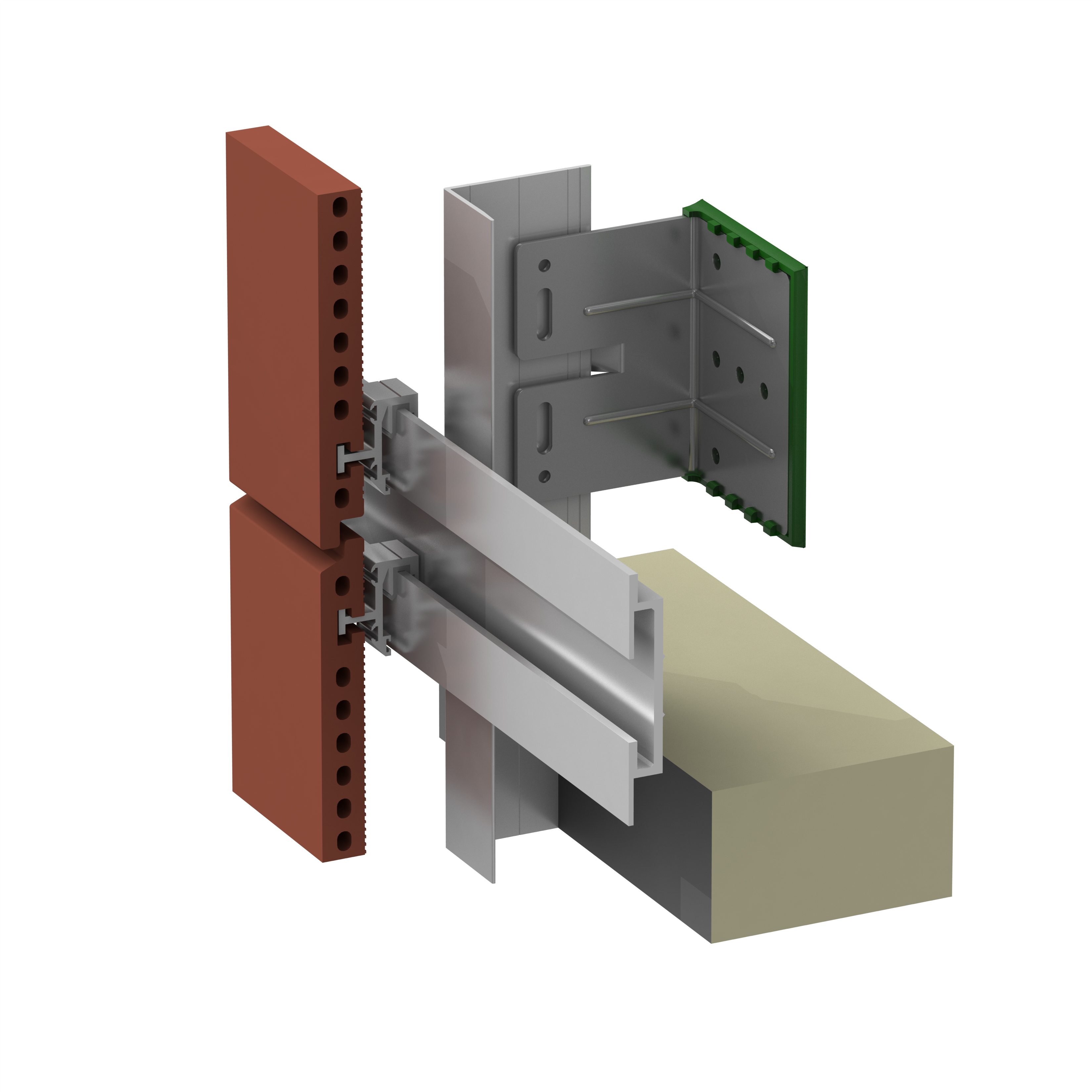

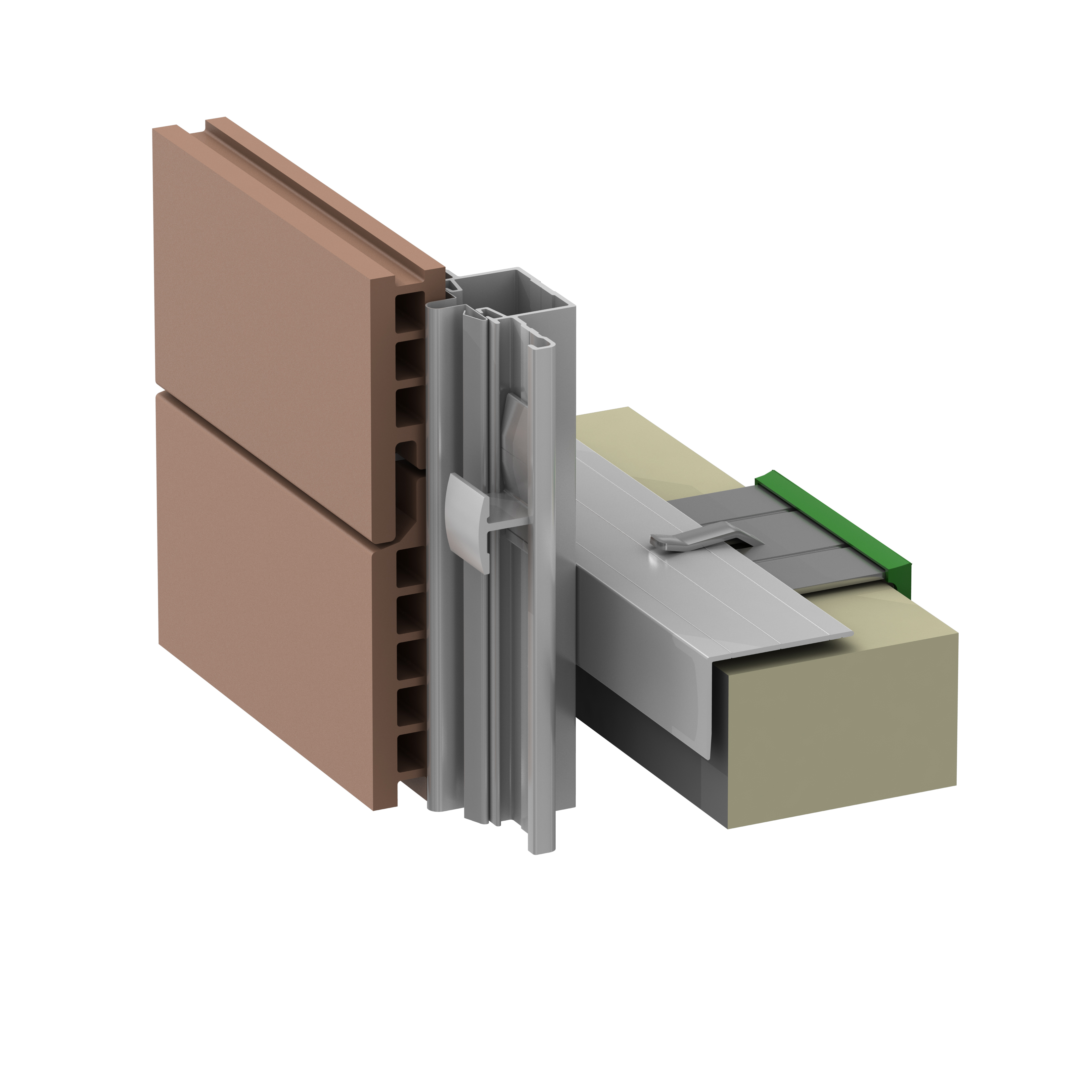

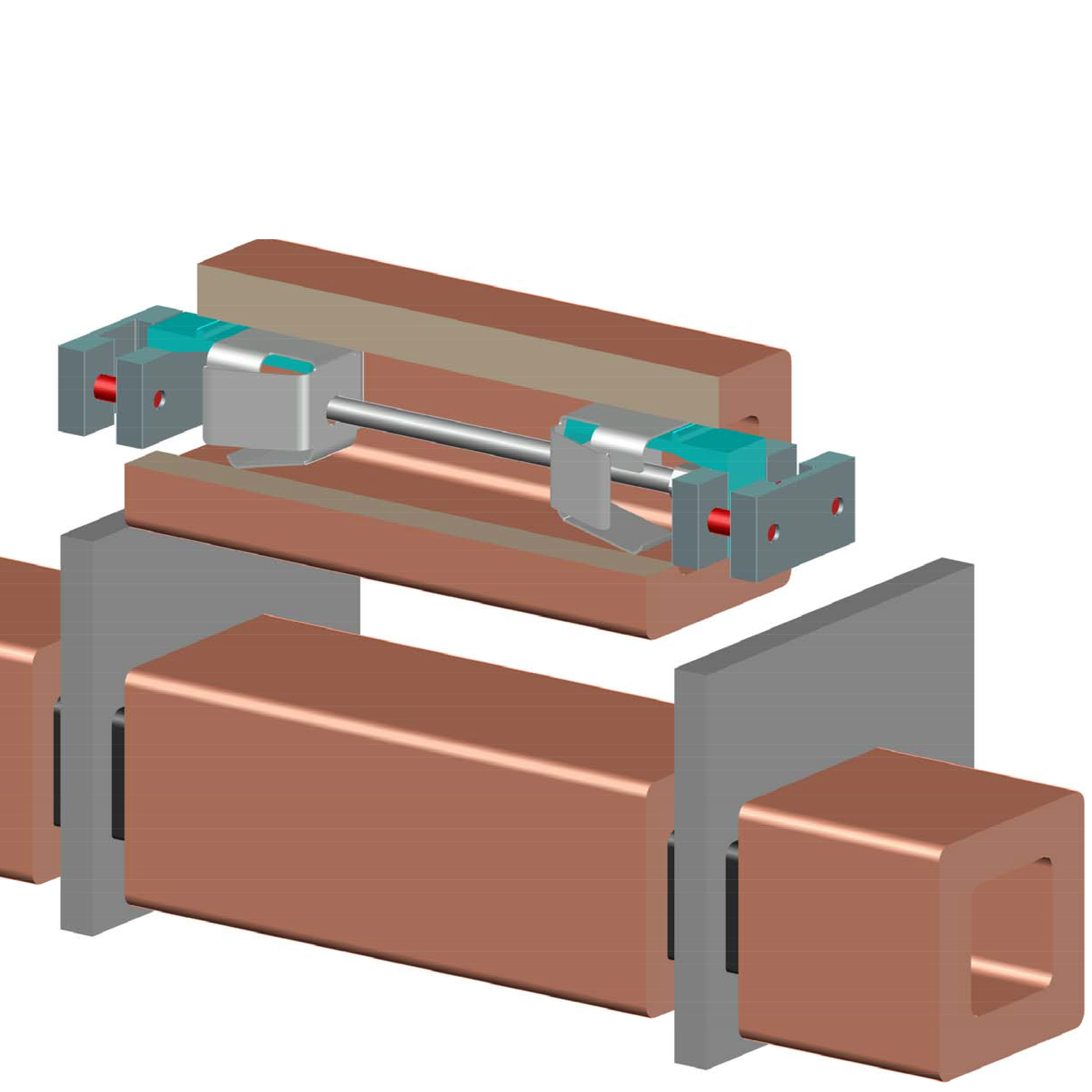

Edge to Edge Spanning with Alpha E Brackets - ECI - C.I. Sub-framing System

This “edge to edge” wall bracket is specifically designed to be fixed to concrete floor slabs. This unique, engineered support system is capable of spanning story heights without the need for intermediate fixings. The system is individually constructed and fabricated for each project, making it ideal for over-cladding medium and highrise buildings.

ECO Cladding's Alpha E brackets offer high load-carrying capacity and large spans can be achieved with solid supporting beam recess. Each bracket is able to perform a fixed and sliding point function and support floor-to-floor spans for a more cost-effective installation with increased thermal performance.

Our components are made of raw aluminum and stainless steel. These metals qualify as non-combustible per IBC language.