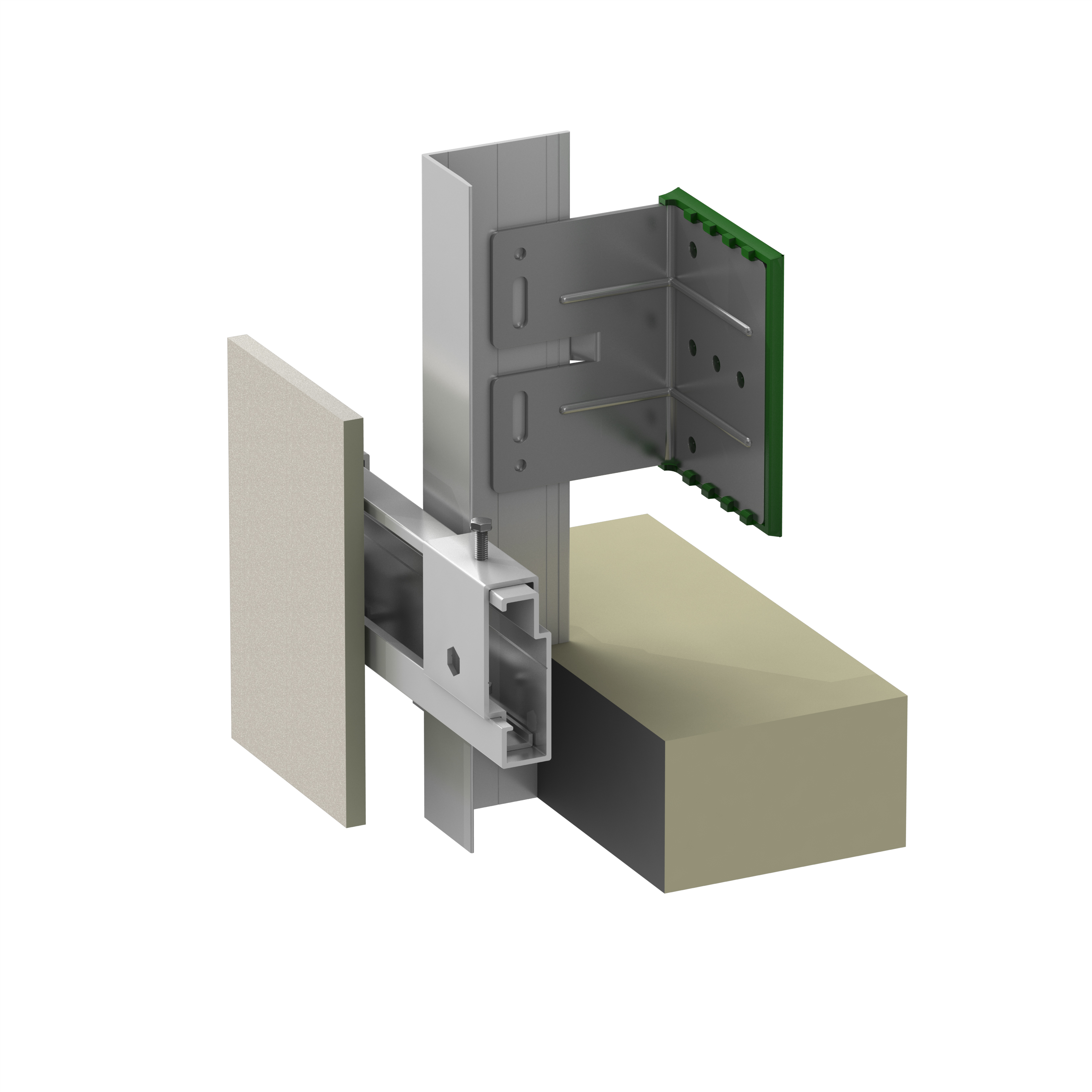

Sigma Vci.40 System

Panel sub-framing system with stainless steel Sigma wall brackets for panel attachment with concealed, undercut anchors for cement composite, ceramic, stone, HPL, and fiber concrete panels. The back of each panel is pre-drilled using an undercut drill bit to receive the hanger clip and expanding bolt anchor.

ECO Cladding’s Sigma U stainless steel brackets have low thermal conductivity and an isolator pad to reduce heat loss and significantly decrease thermal bridging.

Engineered to address dead load, wind load, seismic concerns, thermal requirements, and material deflection for either steel stud or concrete backup conditions.

Key Sigma Vci.40 System Features:

-

Self-adjusting: Up to 1.5” of internal adjustability. Level and plumb not a problem. Cavity depths from 2” to 12”. Helping hand acts like another laborer on your team.

-

Universal Bracket: Both vertical and horizontal orientation can be achieved using one bracket. Stiffening ribs create optimal engineering design.

-

Thermally-broken: Pre-installed isolator pad provides material separation and thermal break. Made of enhanced thermal resistant material. Achieve U-values to meet ASHRAE 90.1. Passive House certified component.

-

Non-combustible: Fire resistance to address fire codes.

-

High-grade Stainless Steel: Grade 304 stainless steel is pre-punched and accommodates heavy rainscreen panels and high wind loads.

-

Recycled Content: Excellent recycled content profile with 18.29% pre-consumer and 63.77 post-consumer.

-

Engineered System: Fixed and Sliding Points allow for expansion and contraction of the subframe system. One to three anchor design create numerous economically efficient engineering solutions.

-

Made in USA: USA-made steel. Buy America / Buy American Advantage.