Alpha V Bracket - Vertical

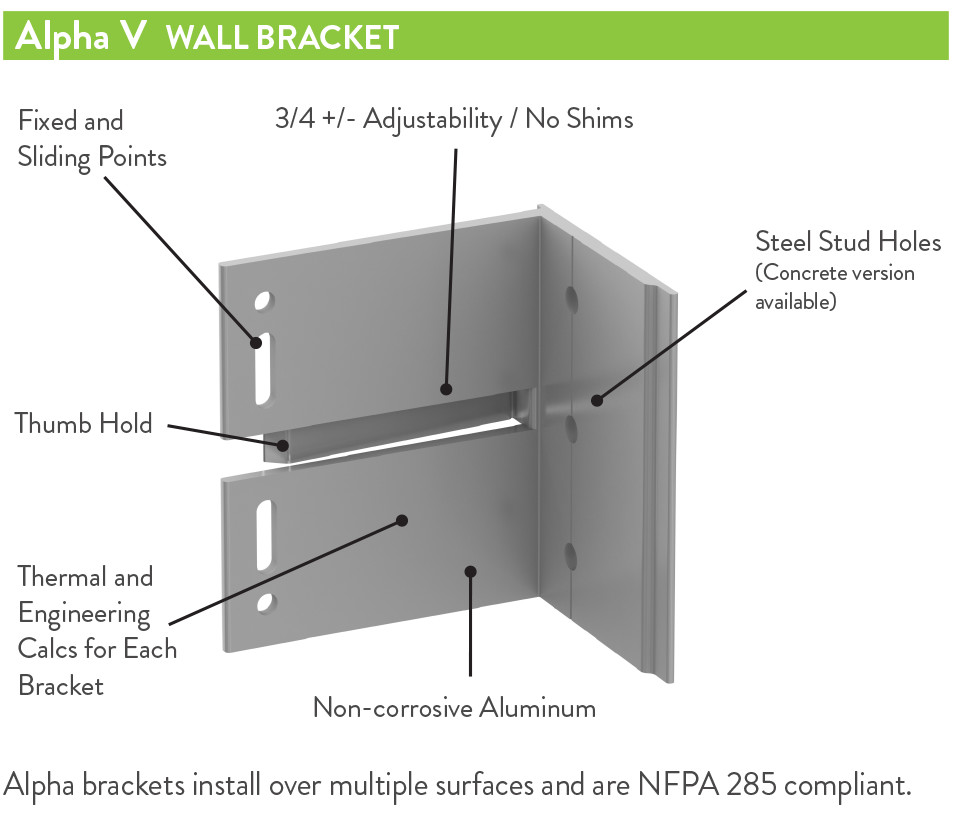

Our Alpha Series of wall brackets are extruded from aluminum and are the building blocks used to simplify the process of building rainscreen walls of all types including CI Subframing and Panel Subframing. Alpha V aluminum brackets are a part of our vertical-mounted cladding support system. They come in a wide range of sizes to meet the needs of light and heavy loads. Wind shear tests have been done to accommodate the most extreme weather conditions. The tight thermal cavity our system provides will help your building save on energy costs for years to come.

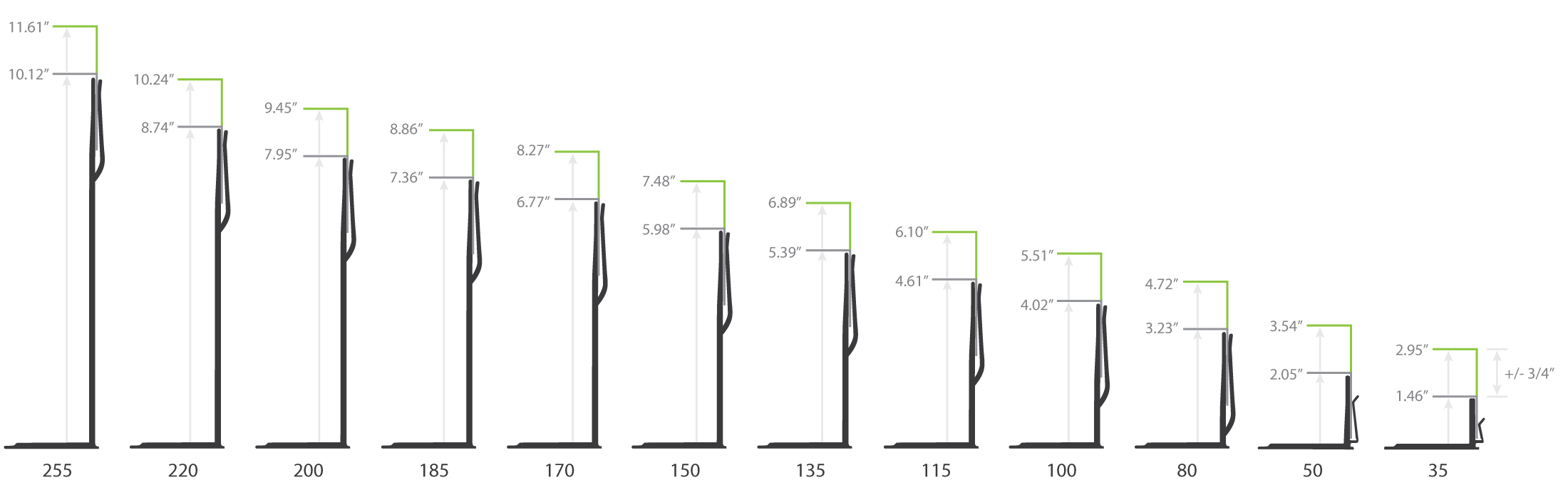

Alpha V aluminum wall brackets come in twelve sizes to create various system cavity depths. Based on various load requirements, the number of fasteners back into the sub-structure will be defined. Alpha V+ aluminum brackets allow more fastener points and can be used in combination with Alpha V brackets to address the cladding material’s dead load.

All of our aluminum Alpha wall brackets are extruded with 6063-T6, copper-free and “marine-grade” aluminum. For rainscreen applications, the non-corrosive nature of aluminum makes it a perfect material to use. Since aluminum is more elastic than steel, it is especially ideal for creating precise parts for deep and straight walls and is efficient to fabricate with most punching and extrusion machines. Aluminum is the preferred material for curtainwalls and will become the same for cladding support systems in North America.

Alpha V Bracket Dimensions

Alpha brackets provide the design community with control and ease in creating wall cavity depths. Our Alpha V vertical brackets come in standard dimensions of 35mm (1.38”) to 255mm (10.04”) and in two sizes (V and V+). Use the appropriate bracket size to meet your exterior insulation requirements! Submit your project to us using our Build Your Project submission process and we can assist!

Alpha V BRACKET ADJUSTABILITY

The Alpha V aluminum wall brackets’ "thumb hold" feature has a +/- 3/4 inch of built-in adjustability to accommodate out-of-plumb conditions found in the field. This allows for a more rapid set of materials and an easier installation without the use of plastic shims.