Design Hint: Don't Isolate - Think Full Systems!

We're not limited to component parts only! ECO Cladding is committed to providing fully-engineered system-based solutions, in which both cladding and substructure are engineered to accommodate project wind loads, seismic loads, building slab to slab deflections, and thermal movements of materials.

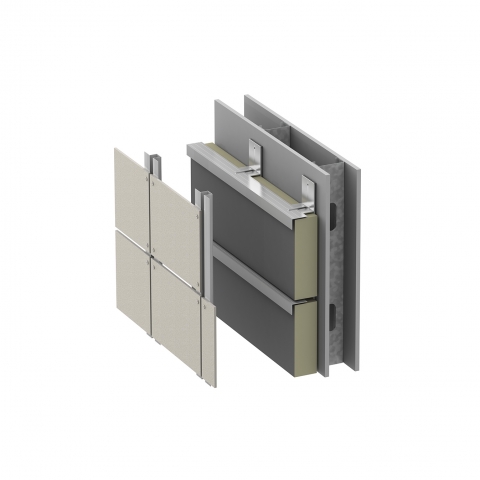

A successful drained and back-ventilated (DBV) rainscreen is not limited to the cladding materials and subframing system alone, it requires an integration of educated design based upon a holistic approach to the exterior envelope. ECO Cladding is an advocate for this “outside-in” approach, starting with the selection of the cladding material and ending with the inner waterproofing of the wall.

Why is this important? With an ever-increasing shift towards sustainable design, the exterior envelope of the building offers some of the most significant opportunities to create high-performance buildings that leave the least impact on the environment. ECO Cladding provides a fully-integrated rainscreen approach that begins with the outer skin of the wall and works its way back to the air/water barrier (AWB). Rather than isolating the design of the cladding materials independent of the entire wall assembly, ECO Cladding designs with a focus on all of the scientific principals and elements required to create an effectively designed drained and back-ventilated rainscreen assembly.

During the Design Phase, we encourage beginning with the cladding material selected. It is critical to understand the material deflection and thermal properties, spanning capabilities, and water absorption of the cladding material, as these factors will influence the engineering of the substructure and the overall wall assembly. Our Complete System Selector enables you to search for the system based on cladding material type. Next, comes consideration for the panel joint design and depth of cavity space behind the wall cladding. During this process, you must consider the degree of water infiltration within the system and panel joint design. As you consider cavity depth, you will need to evaluate the goals for insulation, R-values, and depth of the system.

From initial design and detailing assistance to shop drawings and engineered calculations to job site training and final installation, ECO Cladding provides a full range of services as part of our approach to subframing design that guarantees proper installation and long-life performance. Do you have a project in mind? Why not Request a Quote and set up an account that allows us to share the specifics on your project with our technical design team. We look forward to working with you!