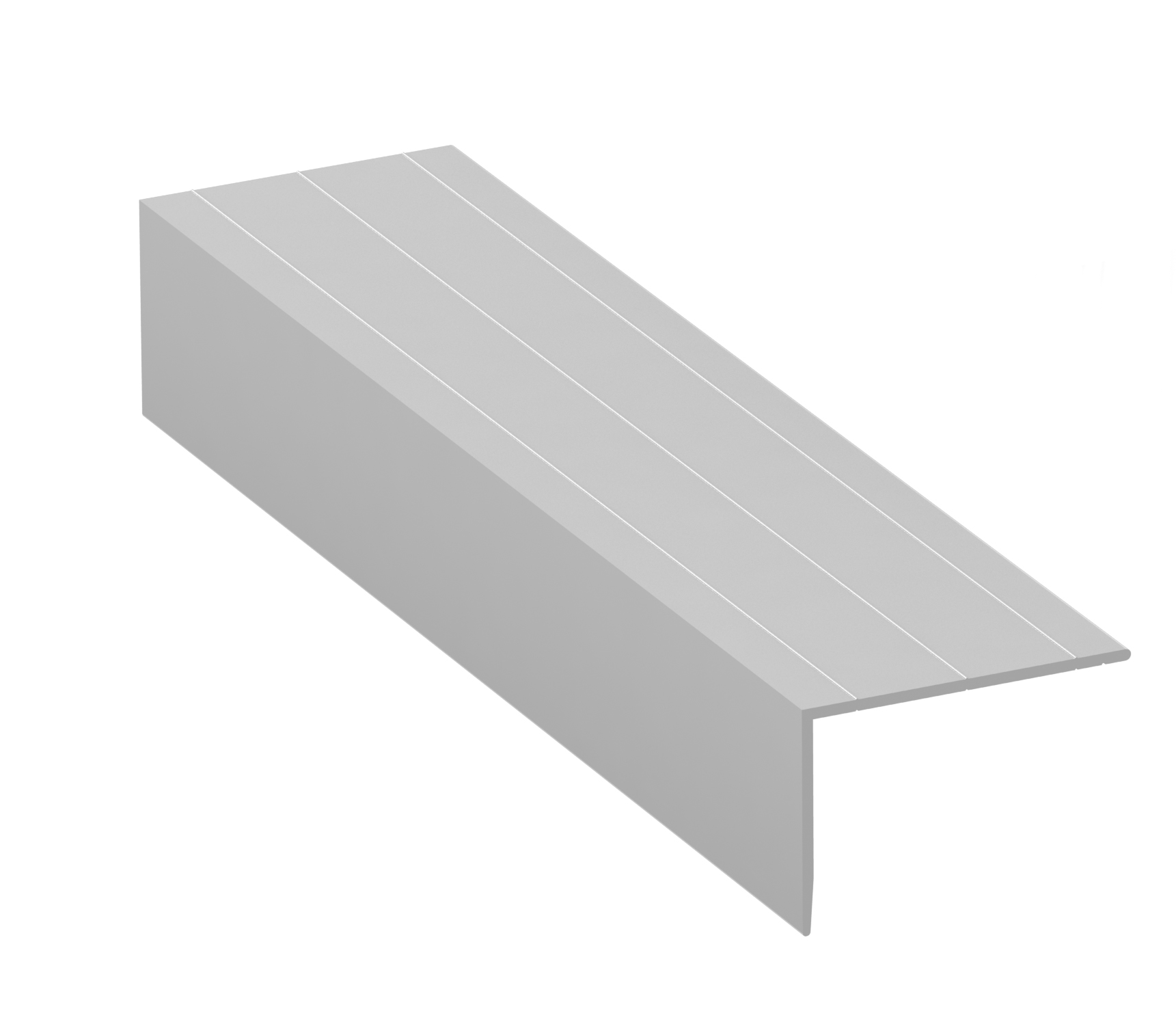

Sigma U Wall Brackets (Stainless Steel)

Thermal bridging can be responsible for a structure’s heat loss. ECO Cladding’s Sigma U (Universal) stainless steel brackets have low thermal conductivity, helping to reduce energy loss and meet performance standards. The attached isolator pad is designed without holes to create a watertight seal, assist with water management, and provide separation between dissimilar materials at the substrate.

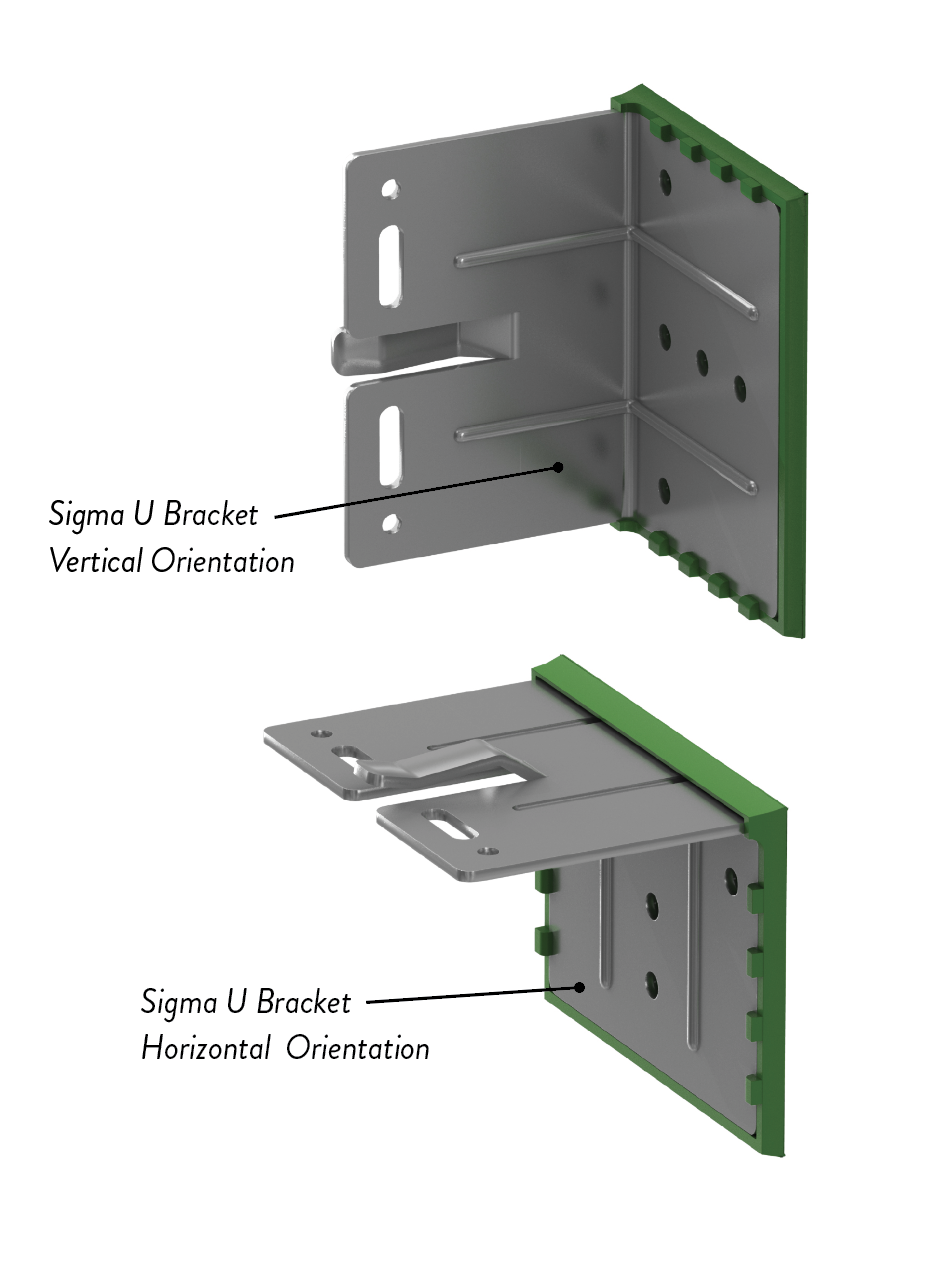

Sigma U Brackets are designed to simplify the building rainscreen walls of all types by providing one ‘universal bracket’ for both horizontal and vertical orientation. Both vertical and horizontal are achieved in one bracket. Stiffening ribs create optimal engineering design. Sigma U Brackets are available in multiple sizes to create various cavity depths. The number of fasteners back into the substructure will be optimized based on load requirements and backup wall type.

Not just universal... address your building’s U-value with Sigma U Brackets.

Sigma U - Universal Wall Bracket

With the Sigma U wall bracket - both vertical and horizontal orientations are achieved in one "universal" stainless steel bracket. Stiffening ribs create optimal engineering design. The pre-installed isolator pad is designed to create a tight seal at the connection point, helping to prevent water penetration into the wall assembly. It provides material separation between dissimilar substrates, reducing the risk of galvanic corrosion and long-term deterioration. Achieve U-values to meet ASHRAE 90.1. Grade 304 stainless steel offers an excellent recycled content profile with both 18.29% pre-consumer and 63.77% post-consumer recycled content.

ECO Cladding’s Sigma stainless steel brackets have a low thermal conductivity which reduces heat loss and significantly decreases thermal bridging.

Alpha Wall Brackets (Aluminum)

All of our Alpha wall brackets are extruded with 6063-T6, copper-free, and “marine-grade” aluminum. Aluminum is a silvery-white, nonmagnetic, ductile metal. Aluminum is the #1 most abundant metal in the Earth’s crust, chief ore is bauxite, and the third most abundant element. The material has a density of 2.7kg/m3, is lightweight, and stronger than steel. The malleable qualities of aluminum make it perfect to extrude. Aluminum can go places and create shapes that steel cannot, often forming deeper or more intricate shapes. For rainscreen applications, the non-corrosive nature of aluminum makes it a perfect material to use. Since aluminum is more elastic than steel, it is especially ideal for creating precise parts for deep and straight walls and is efficient to fabricate with most punching and extrusion machines. Aluminum is the preferred material for curtainwalls and has become a predominant player in cladding support systems in North America. All of ECO Cladding’s system components are non-combustible and are not triggers for the NFPA 285 requirements in the IBC.

Vertical Solution - Alpha V Bracket

Alpha brackets are designed to simplify the process of building rainscreen walls of all types including C.I. Sub-framing and Panel Sub-framing.

Our Vertical Alpha V brackets are available in twelve sizes to create various cavity depths. The number of fasteners back into the sub-structure will be optimized based on load requirements and back-up wall type.

Alpha V+ brackets allow more fastener points and can be used in combination with standard Alpha V brackets to address the cladding material’s deadload.

Horizontal Solution - Alpha H Bracket

Alpha brackets are the building blocks designed to simplify the process of building rainscreen walls of all types including C.I. Sub-framing and Panel Sub-framing.

Our horizontal Alpha H brackets come in eight sizes to create various system cavity depths. Based on various load requirements, the number of fasteners back into the substructure will be optimized based on load requirements and back-up wall type.

Alpha H+ brackets allow more fastener points and can be used in combination with standard Alpha H brackets to address the cladding material’s deadload, specifically for concrete block construction.

Edge to Edge Solution - Alpha E Bracket

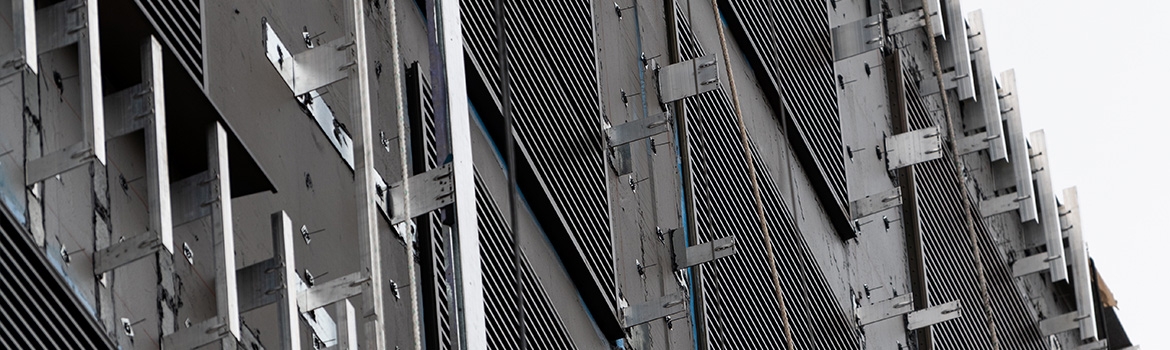

This “edge to edge” bracket is specifically designed to be fixed to concrete floor slabs. This unique, engineered support system is capable of spanning story heights without the need for intermediate fixings. The system is individually constructed and fabricated for each project, making it ideal for over-cladding medium and high rise buildings.

Alpha E Brackets offer high load-carrying capacity and large spans (floor to floor) can be achieved due to a solid supporting beam recess. Each bracket is able to perform a fixed and sliding point function, with adjustability range from 1.5" to 3.5" based on bracket and tube size.

Rails & Accessories

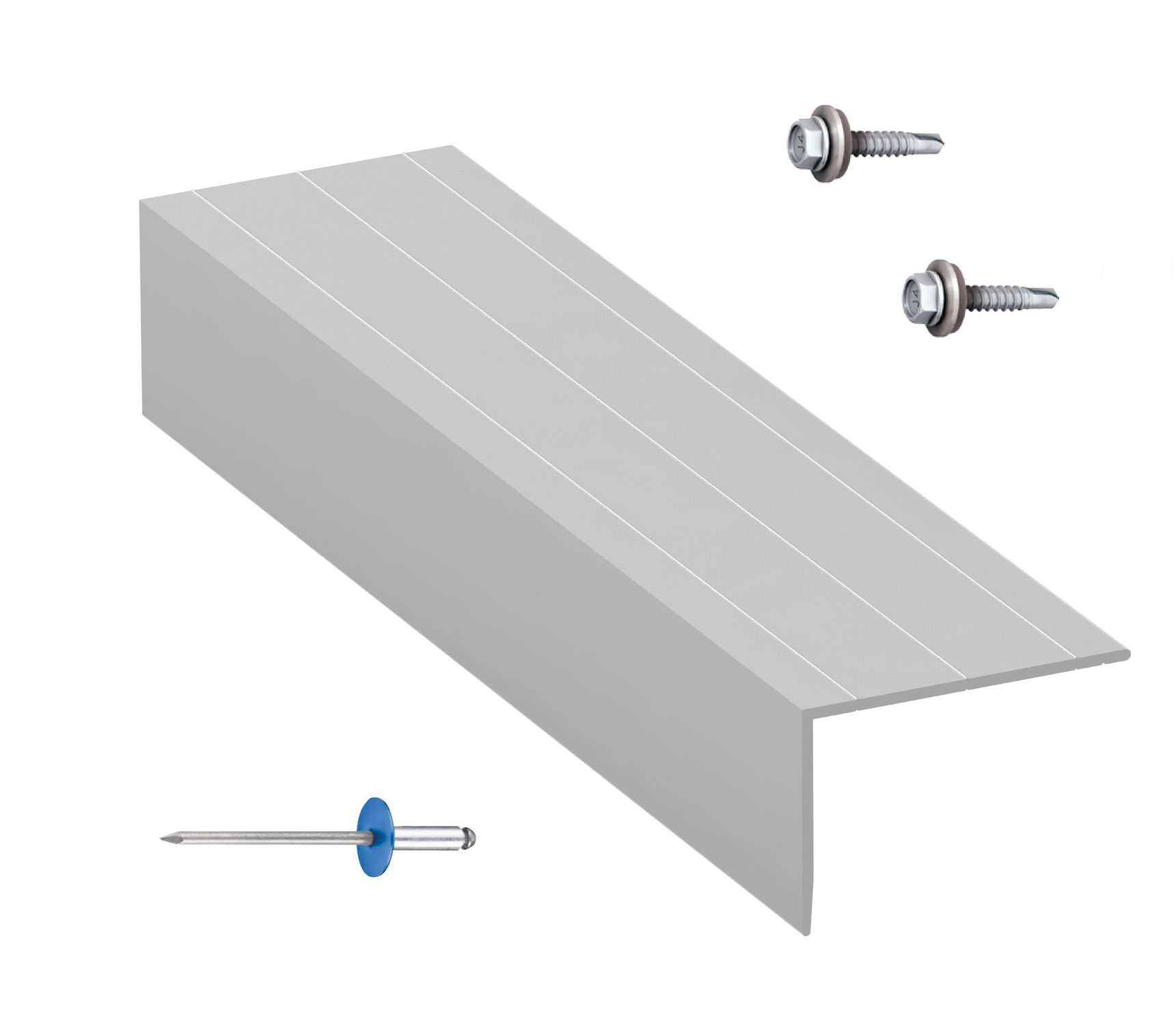

It is our goal to provide installers with all of the items needed to get your project properly installed. In addition to profile rails, ECO Cladding can provide the fixing tools, joint profiles, fasteners, rivets, centering tools, drill bits, vent profiles and installation tools necessary for a successful installation.

Profile Rails

In addition to our fully-engineered solutions for C.I. Sub-framing and Panel Sub-framing, ECO Cladding maintains significant reserves of all of our stock profile rails, available for applications where individual components are necessary. Cut profile lengths that can be project-specific and custom solutions are also available.

Accessories

It is our goal to provide installers with all of the items needed to get your project properly installed. In addition to profile rails, ECO Cladding can provide the fixing tools, joint profiles, fasteners, rivets, centering tools, drill bits, vent profiles and installation tools necessary for a successful installation.